9th Khetwadi Ln, Girgaon, Mumbai, Maharashtra 400004

ASME SA 335 P5 Alloy Steel Seamless Pipe and ASTM A335 P5B Pipe supplier in India

Check IBR certified SA 335 P5C pipe outer diameter, wall thickness and length as per ANSI/ ASME B36.10M. Get ASTM A335 P5 Steel Material and SA335 P5 Round Pipe with Testing & Certification

What Is ASTM A335 P5 Pipe Vs ASTM A335 P5 Tube

Pipes and tubes are important piping modules that play a pivotal role in the ASTM A335 P5 grade. These versatile components can be distinguished based on certain key features.

- ASTM A335 P5 pipe can only be produced in a circular cross-section. A tube in the A335 P5 range can be availed in circular, rectangular, and square cross-sections.

- Pipe grades can only be hot rolled. ASTM A335 P5 tube can be both hot and cold rolled.

- A335 P5 Pipe is employed in larger diameter applications, while the latter is preferred for small diameter items.

- Pipes of the A335 P5 require special equipment to precisely shape the piping modules. Tubings can be shaped easily without requiring special equipment.

- A tube is a robust module and possesses more strength in comparison to a pipe.

Looking for ASTM A335 P5 Alloy Steel Pipe suppliers? We stock a full range of Galvanised & Coated SA335 gr P5 High Temperature Seamless Pipe in India. check chemical composition and Mechanical Properties.

ASTM A335 P5 Pipe Vs ASME Sa 335 P5 Pipe

ASTM and ASME are two important standards that are employed in manufacturing pipes in the A335 P5 grade. Both these standards are nearly identical but can be distinguished based on key features.

- ASTM A335 P5 pipe covers a standard where the shapes, sizes, and structural qualities of different piping items are accessed. ASME Sa 335 P5 Pipe comes under a standard that specifies design codes and standards for different pressure-rated applications.

- ASME grade covers nearly 600 technical standards, while ASTM grade covers approximately 12,000 or more standards.

What Is ASTM A335 Gr P5 Pipe Hardness ?

ASTM A335 Gr P5 pipe is designed to have a hardness constant of not more than 250 HB.

Exporter & supplier of NBR 5603 P5 Chrome Moly Pipe and Low Alloy ASTM A335 P5 Steel Pipe with competitive pricing, Supply Thin wall size Steel Grade P5 ASTM A335 High Pressure Seamless Pipe suitable for harsh environment & thermal plant

What Are The Different Types Of NBR 5603 P5 Pipe ?

ASTM A335 P5 Pipe

Alloy Steel P5 Pipes

UNS K41245 Pipe

ASME SA 335 P5 Welded Pipe

Alloy Steel A335 P5 Material

ASTM A335 Gr P5 Boiler Steel Pipe

Steel Grade P5 Seamless Pipe

Low Alloy ASTM A335 P5 Steel Pipe

ASTM A335 P5b Pipe

Manufacturer of ASTM A335 P5 Alloy Steel Pipe and Steel Grade P5 Seamless Pipe in India, get custom size high strength SA335P5 Seamless Pipe in round, square and rectangular shape

Welding Producer ASTM A335 P5 Pipe

IBR / Non IBR ASTM A335 grade P5 Alloy Pipe and Alloy Steel A335 P5 Chrome Pipe distributor & stockist in Mumbai. Don't forget to check our price of Low Alloy ASTM A335 P5 Welded Pipe and after sales services

Steel Gr P5 Pipe Coating Types

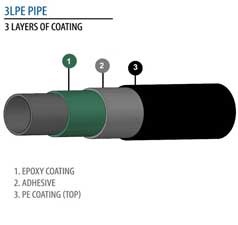

3LPE Coated

SA 335 Gr P5 3LPE Coated Pipes

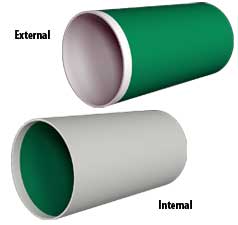

Liquid Epoxy (LE)

ASTM A335 P5 LE Liquid Epoxy Coated Pipe

FBE Coated

ASTM A335 P5 steel FBE Coated Pipe