9th Khetwadi Ln, Girgaon, Mumbai, Maharashtra 400004

ASTM B564 UNS N06625 SORF/ WNRF Flange and Nickel Alloy 625 Blind Flanges manufacturer in India

Why don't you directly contact an Inconel Flanges manufacturer? we supply a complete range of SB 564 UNS N06625 Blind Flange and Nickel Alloy 625 Slip On Flange, ASME SB 564 UNS N06625 Weld Neck & Forged Flange in India

What are Inconel 625 Flanges?

Inconel 625 flanges are austenitic stainless steel grade. These flanges are designed with a superior chemical composition of nickel, chromium, and molybdenum, giving them superior oxidation resistance properties. The Inconel flanges in this grade show enhanced resistance to pitting and in carburizing environments. The high-strength modules are used in temperatures from sub-zero up to 1800 degrees F. The flange type securely seals different piping components and can be readily welded in place following standard welding procedures.

Exporter & supplier of ASTM B564 N06625 BLRF/ WNRF flange in India, lowest price of WNR 2.4856 Orifice flange & Alloy 625 Blind Flange, view 625 Inconel Weld Neck Flange dimensions, sizes and weight chart

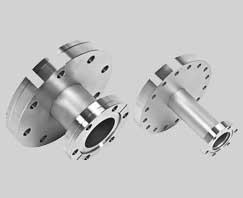

ASTM B564 UNS N06625 Weld Neck Flanges Vs Alloy 625 Ring Type Joint Flange

Flanges are piping constituents that are designed in different face types and load-bearing capacities. Amongst this are the weld neck and ring-type joint flange, both having distinct characteristics.

- ASTM B564 UNS N06625 Weld Neck flange is designed possessing a long protruding hub or face. Alloy 625 Ring Type Joint flange is a metallic ring that has cuts or grooves in its face.

- WNFR flanges are welded directly to the pipe fixture using a butt-weld. RTJ flanges are generally bolted in place, making use of nuts or bolts.

Stocking distributor of Alloy 625 Threaded and Socket Weld Flanges and Inconel 625 Ring Type Joint Flange accordance to ASME B16.5, Check Inconel Alloy 625 Orifice Flanges and Inconel 625 UNS N06625 Lap Joint Flange material standard & pressure class, we also accept 1pc order to large quantity

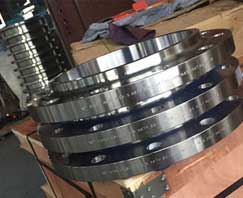

Nickel 625 Blind Flange Vs ASME B16.5 Inconel 625 Slip on Flange

Blind and slip on flanges are common flange types in the alloy 625 grade. Both these flange types can be distinguished from certain features.

- Nickel 625 blind flanges are designed without a face type. ASME B16.5 Inconel 625 slip on flange possess a low profile head.

- Slip on flanges are preferred in low-pressure and temperature setups. Blind flanges seal high pressure and temperature fluids and gases.

- Alloy 625 slip on flanges are welded in place by sliding the flange on different piping modules and fitting it with a fillet weld. Alloy 625 blind flange is bolted in place to seal different piping items.

Exporter of Nickel Alloy 625 Weld Neck Flange and DIN 2.4856 Socket Weld Flange with Final visual inspection & MTR, Check Uns N06625 Slip On Flange Class 150 to 2500 Pressure Rating and Price list

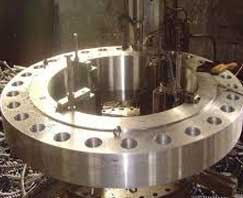

Why is DIN 2.4856 Flanges so hard to machine?

DIN 2.4856 flanges are designed with higher tensile and yield strengths compared to other stainless steel grades. The higher strength makes these flanges hard to machine.

Check Inconel 625 DIN 2.4856 Spectacle Blind, Forged, Plate Long Weld Neck Flange and SB 564 UNS N06625 Threaded Flange material Weight & Dimensions, Stock of DIN 2.4856 Inconel 625 LWRF/ WNRF Flanges in Asia, get a free sample now!

Types of Inconel 625 Flanges