ASTM A312 Tp 409 Welded Pipe and SS 409 ERW Tube Supplier in India

What Is 409 Stainless Steel Pipe?

Stainless steel 409 pipes are part of a ferritic steel grade. The pipes of this grade contain low alloying material with a small content of titanium used to stabilize them. The versatile range exhibits superior corrosion resistance properties and has a temperature range up to 675 degrees C. The robust SS 409 pipes showcase excellent mechanical properties and can be readily welded in place following standard welding procedures.

Can 409 Stainless Be Polished?

The SS 409 can be polished to give it an aesthetically pleasing appeal. The polished grade showcases a bright finish that doesn’t allow corrosive media to form on the piping modules.

What Type Of Material Is 409

The 409 grade of stainless steel is a heat-resisting ferritic grade that has good oxidation and corrosion resistance properties.

Is 409 Stainless Steel Good For Exhaust Pipe

The 409 stainless steel grade is primarily designed for use in the exhaust industry. The piping modules work well in elevated temperatures and protect the pipe against corrosive media across different stress-induced environments. The pipes in this grade have moderate strength and excellent formability, allowing them to be shaped precisely. Apart from this, the pipes are cheaper to produce, further making them a good choice for exhaust systems.

ASTM A312 Tp 409 Welded Pipe and SS 409 ERW Tube

- ASTM A312 Tp 409 welded pipe is welded in place by joining pieces of sheets or strips either longitudinally or horizontally. Erw 409 tube is manufactured by cold rolling strips and welding it longitudinally.

- Tubes can be shaped in the form of a square, rectangle, or circle. Pipes are usually shaped in a circular cross-section.

- SS 409 ERW tubes are stronger and possess more stability than a welded pipe.

Table of Content

409 Stainless Steel Pipes Specifications, Sizes And Schedules

| Specifications | ASTM/ASME A 312/ SA 312 |

|---|---|

| Size | 1/8″NB to 30″NB IN |

| Dimensions | ASME, ASTM and API |

| Schedule | Schedule20, Schedule30, Schedule40, STD, Schedule80, XS, Schedule60, Schedule80, Schedule120, Schedule140, Schedule160, XXS |

| SS 409 Pipes | 1/2 NB to 16 NB |

| Type | Seamless / ERW / Welded / Fabricated / LSAW Pipes |

| ERW 409 Pipes | 1/2 NB to 24 NB |

| Form | “U” Shape, Custom Pipes, Round Pipes, Hydraulic Pipes |

| EFW 409 Pipes | 6 NB to 100 NB |

| End | Beveled End, Plain End, Treaded |

| Length | Double Random, Single Random, & Cut Length. |

Get details of SS 1.4151 ERW Pipe and Austenitic Stainless Steel 409 Railing Pipe. Refer ASTM A312 tp409 Tube Chemical and Mechanical Requirements.

ASTM A312 Stainless Steel 409 Pipes Composition Chart

| Grade | Si | C | Sl | Mg | Cr | Ph | Ni | Ti | |

|---|---|---|---|---|---|---|---|---|---|

| 409 | Min | – | – | – | – | 10.5 | – | – | 6xC |

| max | 1 | 0.08 | 0.045 | 1 | 11.75 | 0.045 | 0.5 | – |

SS 409 Pipes Mechanical Properties Analysis

| Grade | Elongation % | Tensile Strength MPa (min) | Hardness (Brinell) MAX | Yield Strength 0.2% MPa(min) | Hardness (Rockwell B) MAX |

|---|---|---|---|---|---|

| 409 | 20 | 380 | 207 | 207 | 95 |

Equivalent Material Of Stainless Steel UNS S40900 Pipes

| STANDARD | AFNOR | WERKSTOFF NR. | KS | UNS | GOST | JIS | EN |

|---|---|---|---|---|---|---|---|

| SS 409 | – | 1.4512 | STS409 | S40900 | – | SUS409 | – |

TP 409 SS Werkstoff Nr. 1.4151 Pipes Schedule Chart

| NB Sizes | Schedule 5 | Schedule 10 | Schedule 40 | Schedule 80 | Schedule 160 |

|---|---|---|---|---|---|

| 1 1/4″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1/8″ | ✓ | ✓ | ✓ | ✓ | |

| 2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1/4″ | ✓ | ✓ | ✓ | ✓ | |

| 2 1/2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 3/8″ | ✓ | ✓ | ✓ | ✓ | |

| 3″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1/2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 4″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 3/4″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 6″ | ✓ | ✓ | ✓ | ✓ | |

| 1″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 8″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1 1/2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 5″ | ✓ | ✓ | ✓ | ✓ | |

| 14″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 10″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 16″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 12″ | ✓ | ✓ | ✓ | ✓ | ✓ |

Super Ferritic Stainless Steel 409 Capillary Tubing and ASTM A312 Tp 409 Bright annealed tube Supplier in Mumbai, Call Now to Get Stainless Steel 409 Pipe Free sample

SS 409 Round Pipes Size Chart In Mm And Inches

| Wall | Sizes ( O.D.) |

|---|---|

| .095 | 5/8, 2, 1/2, 1 1/2, 1 1/4, 1″ |

| .010 | 3/16, 1/16, 1/8,″ |

| .083 | 7/8, 1 1/4, 1/4, 1 5/8, 2 1/2 ,3, 1 1/2, 1/2, 3/4, 2, 3/8, 1, 1 7/8, 5/8″ |

| .020 | 1/4, 1/16, 5/16, 3/16, 3/8, 1/8″ |

| .109 | 2, 1, 3/4, 1 1/2, 1/2, 1 1/4″ |

| .012 | 1/8″ |

| .120 | 3, 2, 5/8, 1, 1 1/4, 3/4, 1/2, 1 1/2, 7/8, 2 1/2, 2 1/4″ |

| .016 | 1/8, 3/16″ |

| .028 | 3/16, 1/8, 3/4, 1/2, 3/8, 1 1/2, 1/4, 5/16, 1, 2″ |

| .125 | 1 1/2, 3 1/4, 2, 1, 1 1/4, 3, 3/4″ |

| .035 | 7/16, 1 5/8, 3/4, 7/8, 1 1/2, 1/2, 5/16, 5/8, 1 1/4, 16, 2, 1/8, 2 1/4, 3/8, 3/16, 1, 1/4″ |

| .134 | 1″ |

| .049 | 1/2, 1 5/8, 3/4, 3/8, 1, 1/4, 1 1/2, 5/16, 1 1/4, 2 1/4, 16, 5/8, 1 1/8, 7/8, 3/16, 2″ |

| .375 | 3 1/2″ |

| .065 | 3/4, 1/2, 1/4, 1 1/2, 3/8, 1 1/4, 5/8, 3, 2, 16, 1 5/8, 1 3/4, 5/16, 1, 2 1/2, 7/8″ |

| .250 | 3″ |

409 Stainless Steel Electropolished Pipes Physical

| Grade | Elastic Modulus (GPa) | Specific Heat 0-100°C (J/kg.K) | Density (kg/m3) | Mean Coefficient of Thermal Expansion (μm/m/°C) | Electrical Resistivity (nΩ.m) | Thermal Conductivity (W/m.K) | |||

|---|---|---|---|---|---|---|---|---|---|

| 0-100°C | 0-538°C | 0-315°C | at 100°C | at 500°C | |||||

| 409 | 200 | 460 | 7800 | 11.0 | 12.4 | 11.7 | 600 | 25.8 | 27.5 |

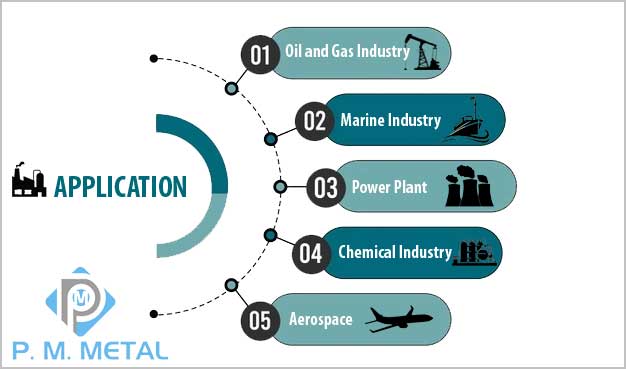

Stainless Steel 409 Seamless Pipes Applications

Basic Types Of ASME SA 358 SS 409 Welded Pipes

SS 409 Hexagonal Pipes Weight Per Foot Chart

| Nominal size [inches] | Outside diameter [inches] | Outside diameter [mm] | Weight [lb/ft] | Weight [kg/m] | Wall thickness [inches] | Wall thickness [mm] |

|---|---|---|---|---|---|---|

| 16 | 16,000 | 406,4 | 192,43 | 286,64 | 1,219 | 30,96 |

| 4 | 4,500 | 114,3 | 19,00 | 28,32 | 0,438 | 11,13 |

| 14 | 14,000 | 355,6 | 150,79 | 224,65 | 1,094 | 27,79 |

| 5 | 5,563 | 141,3 | 27,04 | 40,28 | 0,500 | 12,7 |

| 20 | 20,000 | 508,0 | 296,37 | 441,49 | 1,500 | 38,10 |

| 6 | 6,625 | 168,3 | 36,39 | 54,20 | 0,562 | 14,27 |

| 22 | 22,000 | 559,0 | 353,61 | 527,02 | 1,625 | 41,28 |

| 8 | 8,625 | 219,1 | 60,71 | 90,44 | 0,719 | 18,26 |

| 24 | 24,000 | 610,0 | 429,39 | 640,03 | 1,812 | 46,02 |

| 10 | 10,750 | 273,0 | 89,29 | 133,06 | 0,844 | 21,44 |

| 18 | 18,000 | 457,0 | 244,14 | 363,56 | 1,375 | 34,93 |

| 12 | 12,750 | 323,8 | 125,49 | 186,97 | 1,000 | 25,4 |

View Martensitic Stainless Steel 409 Heat exchanger Tubes and ASME SA 312 Tp 409 Condenser Tubing sizes chart in mm

TP 409 Stainless Steel ERW / EFW Pipes Dimension

| Pipe Size (in) |

Nominal Thickness (in) mm |

Diameter (in) mm |

Volume (ft3/ft) |

Transverse Areas (in2) mm2 |

Length of Pipe (ft per sq. foot of surface) |

Number of Threads per inch of Screw | Weight | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| External | Internal | External | Steel | Internal | External Surface (ft) |

Internal Surface (ft) |

(lb/ft) | (kg/m) | ||||

| 5 | 0.26 | 5.563 | 5.05 | 0.1389 | 24.30 | 4.30 | 20.00 | 0.69 | 0.76 | 8 | 14.61 | 21.74 |

| 1/8 | 0.07 | 0.405 | 0.27 | 0.0004 | 0.13 | 0.07 | 0.06 | 9.43 | 14.20 | 27 | 0.24 | 0.36 |

| 4 | 0.24 | 4.500 | 4.03 | 0.0884 | 15.90 | 3.17 | 12.73 | 0.85 | 0.95 | 8 | 10.79 | 16.06 |

| ¼ | 0.09 | 0.540 | 0.36 | 0.0007 | 0.23 | 0.13 | 0.10 | 7.07 | 10.49 | 18 | 0.42 | 0.63 |

| 8 | 0.32 | 8.625 | 7.98 | 0.3552 | 58.42 | 8.40 | 50.02 | 0.44 | 0.48 | 8 | 28.55 | 42.49 |

| 3/8 | 0.09 | 0.675 | 0.49 | 0.0013 | 0.36 | 0.17 | 0.19 | 5.66 | 7.75 | 18 | 0.57 | 0.84 |

| 10 | 0.37 | 10.750 | 10.02 | 0.5476 | 90.76 | 11.90 | 78.85 | 0.36 | 0.38 | 8 | 40.48 | 60.24 |

| ½ | 0.11 | 0.840 | 0.62 | 0.0021 | 0.55 | 0.25 | 0.30 | 4.55 | 6.14 | 14 | 0.85 | 1.26 |

| 12 | 0.41 | 12.750 | 11.94 | 0.7763 | 127.64 | 15.74 | 111.90 | 0.30 | 0.32 | 8 | 53.60 | 79.77 |

| ¾ | 0.11 | 1.050 | 0.82 | 0.0037 | 0.87 | 0.33 | 0.53 | 3.64 | 4.64 | 14 | 1.13 | 1.68 |

| 6 | 0.28 | 6.625 | 6.07 | 0.2006 | 34.47 | 5.58 | 28.89 | 0.58 | 0.63 | 8 | 18.97 | 28.23 |

| 1 | 0.13 | 1.315 | 1.05 | 0.0060 | 1.36 | 0.49 | 0.86 | 2.90 | 3.64 | 11 ½ | 1.68 | 2.50 |

| 16 | 0.50 | 16.000 | 15.00 | 1.2230 | 201.05 | 24.35 | 176.70 | 0.24 | 0.25 | 8 | 78.00 | 116.08 |

| 1 ¼ | 0.14 | 1.660 | 1.38 | 0.0104 | 2.16 | 0.67 | 1.50 | 2.30 | 2.77 | 11 ½ | 2.27 | 3.38 |

| 14 | 0.44 | 14.000 | 13.13 | 0.9354 | 153.94 | 18.64 | 135.30 | 0.27 | 0.28 | 8 | 63.00 | 93.75 |

| 1 ½ | 0.15 | 1.900 | 1.61 | 0.0141 | 2.84 | 0.80 | 2.04 | 2.01 | 2.37 | 11 ½ | 2.72 | 4.04 |

| 18 | 0.56 | 18.000 | 16.88 | 1.5550 | 254.85 | 30.85 | 224.00 | 0.21 | 0.23 | 8 | 105.00 | 156.26 |

| 2 | 0.15 | 2.375 | 2.07 | 0.0233 | 4.43 | 1.08 | 3.36 | 1.61 | 1.85 | 11 ½ | 3.65 | 5.43 |

| 20 | 0.59 | 20.000 | 18.81 | 1.9260 | 314.15 | 36.15 | 278.00 | 0.19 | 0.20 | 8 | 123.00 | 183.05 |

| 2 ½ | 0.20 | 2.875 | 2.47 | 0.0333 | 6.49 | 1.70 | 4.79 | 1.33 | 1.55 | 8 | 5.79 | 8.62 |

| 24 | 0.69 | 24.000 | 22.63 | 2.7930 | 452.40 | 50.30 | 402.10 | 0.16 | 0.17 | 8 | 171.00 | 254.48 |

| 3 | 0.22 | 3.500 | 3.07 | 0.0513 | 9.62 | 2.23 | 7.39 | 1.09 | 1.25 | 8 | 7.58 | 11.27 |

| 3 ½ | 0.23 | 4.000 | 3.55 | 0.0687 | 12.56 | 2.68 | 9.89 | 0.95 | 1.08 | 8 | 9.11 | 13.56 |

TP SS 409 Hollow Pipes Pressure Rating

| SS Pipe Size(inches) | SS Pipe Schedule | Temperature(F) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 100 | 200 | 300 | 400 | 500 | 600 | 650 | 700 | 750 | ||

| 1 1/2″ | 40 | 2257 | 1947 | 1750 | 1608 | 1496 | 1425 | 1383 | 1354 | 1340 |

| 80 | 3182 | 2744 | 2466 | 2267 | 2108 | 2009 | 1949 | 1909 | 1889 | |

| 160 | 4619 | 3984 | 3580 | 3291 | 3060 | 2916 | 2829 | 2772 | 2743 | |

| 1″ | 40 | 3048 | 2629 | 2362 | 2171 | 2019 | 1924 | 1867 | 1824 | 1810 |

| 80 | 4213 | 3634 | 3265 | 3002 | 2791 | 2659 | 2580 | 2528 | 2501 | |

| 160 | 6140 | 5296 | 4759 | 4375 | 4068 | 3876 | 3761 | 3684 | 3646 | |

| 2″ | 40 | 1902 | 1640 | 1474 | 1355 | 1260 | 1201 | 1165 | 1141 | 1129 |

| 80 | 2747 | 2369 | 2129 | 1957 | 1820 | 1734 | 1682 | 1648 | 1631 | |

| 160 | 4499 | 3880 | 3486 | 3205 | 2980 | 2840 | 2755 | 2699 | 2671 | |

| 4″ | 40 | 1531 | 1321 | 1187 | 1091 | 1014 | 967 | 938 | 919 | 909 |

| 80 | 2213 | 1909 | 1715 | 1577 | 1466 | 1397 | 1355 | 1328 | 1314 | |

| 160 | 3601 | 3106 | 2791 | 2566 | 2386 | 2273 | 2206 | 2161 | 2138 | |

| 3″ | 40 | 1806 | 1558 | 1400 | 1287 | 1196 | 1140 | 1106 | 1084 | 1072 |

| 80 | 2553 | 2202 | 1979 | 1819 | 1691 | 1612 | 1564 | 1532 | 1516 | |

| 160 | 3840 | 3312 | 2976 | 2736 | 2544 | 2424 | 2352 | 2304 | 2280 | |

| 6 | 40 | 1219 | 1052 | 945 | 869 | 808 | 770 | 747 | 732 | 724 |

| 80 | 1913 | 1650 | 1483 | 1363 | 1267 | 1208 | 1172 | 1148 | 1136 | |

| 160 | 3289 | 2836 | 2549 | 2343 | 2179 | 2076 | 2014 | 1973 | 1953 | |

| 10″ | 40 | 974 | 840 | 755 | 694 | 645 | 615 | 596 | 584 | 578 |

| 80 | 1609 | 1388 | 1247 | 1147 | 1066 | 1016 | 986 | 966 | 56 | |

| 160 | 3147 | 2714 | 2439 | 2242 | 2085 | 1986 | 1927 | 1880 | 1868 | |

| 5″ | 40 | 1342 | 1158 | 1040 | 956 | 889 | 847 | 822 | 805 | 797 |

| 80 | 1981 | 1709 | 1535 | 1411 | 1312 | 1250 | 1213 | 1189 | 1176 | |

| 160 | 3414 | 2945 | 2646 | 2433 | 2262 | 2155 | 2091 | 2049 | 2027 | |

| 8″ | 40 | 1073 | 926 | 832 | 765 | 711 | 678 | 657 | 644 | 637 |

| 80 | 1692 | 1459 | 1311 | 1205 | 1121 | 1068 | 1036 | 1015 | 1005 | |

| 160 | 3175 | 2738 | 2460 | 2262 | 2103 | 2004 | 1944 | 1905 | 1885 | |

DIN 1.4151 Stainless Steel 409 Pipes Tolerance

| SS 409 Pipe OD | AISI 409 Seamless Pipe Tolerance |

|---|---|

| 4 to 35mm | +/- 0.08mm |

| 35 to 38mm | +/- 0.15mm |

| 38 to 60mm | +/- 0.20mm |

| 60 and above | +/- 0.25mm |

ASTM A276 SS 409 Pipes Surface Finish

| Surface features | Surface roughness (Ra) value | Examples of processing methods |

|---|---|---|

| Dark glossy surface | Ra0.2, Ra0.1, Ra0.05 | Grinding, honing, super-fine grinding, polishing |

| Clearly visible knife marks | Ra100, Ra50, Ra25 | Rough turning, rough planing, rough milling, drilling |

| No visible processing marks | Ra1.6, Ra0.8, Ra0.4 | Fine turning, fine grinding, fine hinge, grinding |

| Slightly seen knife marks | Ra12.5, Ra6.3, Ra3.2 | Fine turning, fine planing, fine milling, rough hinge, rough grinding |

SS TP 409 Seamless Pipes Finish

Stainless Steel 409 Pipes Testing

- Hardness Test

- Intergranular Corrosion (IGC) Test

- Mechanical Testing Such as Tensile of Area

- Positive Material Identification – PMI Testing

- Chemical Analysis – Spectro Analysis

- Micro and MacroTest

- Flattening Test

- Flaring Test

- Pitting Resistance Test

Stockist & Exporter of ASME SA 312 AISI 409 Stainless Steel Tube in Mumbai, Buy Jindal make Stainless Steel 409 Pipe at dealer price in India

SS 409 Pipe Price

inox stainless steel tube ASTM A312 AISI 409

SUS 409 32mm 31mm 30mm dia stainless steel erw exhaust pipe tubes

409 Staibless Steel Tube 2000mm diameter

tp409 8mm stainless steel 409 seamless pipe tube

3/16 Series 409 Ferritic Seamless Round Stainless Steel Solid

ASTM INOX 50mm diameter round stainless steel pipe seamless 409

SS 409 Tube Packaging

409 Stainless Steel Pipes Stock List

| 409 Stainless Steel Pipes | ASTM A312 Tp 409 Bright annealed tube |

| ASTM A312 Stainless Steel 409 Pipes | Stainless Steel Werkstoff NR. 1.4151 Pipes |

| SS 409 Pipes | Martensitic Stainless Steel 409 Heat exchanger Tubes |

| Stainless Steel UNS S40900 Pipes | ASME SA 312 Tp 409 Condenser Tubes |

| TP 409 SS Werkstoff Nr. 1.4151 Pipes | SME SA 312 AISI 409 Stainless Steel Pipe and Tubes |

| SS 409 Round Pipes | DIN 1.4151 Stainless Steel 409 Pipes |

| 409 Stainless Steel Electropolished Pipes | ASTM A276 SS 409 Pipes |

| Stainless Steel 409 Seamless Pipes | SS TP 409 Seamless Pipes |

| ASME SA 358 SS 409 Welded Pipes | Stainless Steel 409 Pipes |

| SS 409 Hexagonal Pipes | SS 409 Hydraulic Pipes |

| TP 409 Stainless Steel ERW / EFW Pipes | SS 409 Tube |

| TP SS 409 Hollow Pipes | 409 Stainless Tube |

| Stainless Steel 409 Pipe | 409 Stainless Steel Exhaust Tubing |

| ASTM A312 Tp 409 Welded Pipe | Buy 409 Ss Pipe |

| SS 409 ERW Tube | SS 409 Hollow Pipes |

| ASME B36.19 UNS S40900 Schedule 40 Pipe | 409 Steel Seamless Tubes |

| ASME SA 312 SUS 409 Round Pipe | 409 Stainless Steel Tubing |

| SS 1.4151 ERW Pipe | 409 Exhaust Pipe |

| Stainless Steel 409 Pipe | 409 Stainless Steel Exhaust Pipe |

| Aisi 409 Pipe | 409 SS Tube |

| 409 Stainless Steel Tube | SS 409 Pipe |

| Austenitic Stainless Steel 409 Railing Pipe | A312 Stainless Steel 409 Tubes |

| ASTM A358 tp 409 EFW pipe | A312 SS 409 Seamless Pipes |

| Grade 409 Stainless Steel Tubes | TP 409 Stainless Steel Welded Tubing |

| Super Ferritic Stainless Steel 409 Capillary Tubing | SS UNS S40900 Pipes |

Before

Choosing Stainless Steel 409 Pipe Suppliers in India first see the Repeat orders from Below Countries

ASTM A312 Stainless Steel 409 Pipes

Bangladesh, Jakarta -Indonesia, Dubai, Los Alamos -Mexico, Hong Kong, Turkey, Argentina, Germany, China, Oman, Saudi Arabia (KSA).

SS 409 Round Pipes

Malaysia, Poland, Romania, Indonesia, Malaysia, Iran, Qatar, New Zealand, Brazil, Netherlands, United Arab Emirates (UAE).

ASME SA 358 SS 409 Welded Pipes

USA, Chile, Ellington -United States, Canada, Sweden, United States, Greece, Singapore, Vietnam, Mexico, Denmark, Thailand, Finland.

SS 1.4151 ERW Pipe

Russia, Belgium, Norway, Egypt, Bahrain, Philippines, South Korea, Peru, Malaysia, Tehran -Iran, Colombia, Italy.

SS 409 Hydraulic Pipes

Spain, Jakarta, Europe, Australia, Jordan, Dammam -KSA, Japan, Istanbul -Turkey, NY 12203 (USA), Dubai -UAE, Kuala Lumpur.

ASTM A312 SS 409 Seamless Pipes

France, Singapore, Taiwan, South Africa, Portugal, Morocco, Czechia, Kuwait, Austria, United Kingdom (UK), Nigeria.