9th Khetwadi Ln, Girgaon, Mumbai, Maharashtra 400004

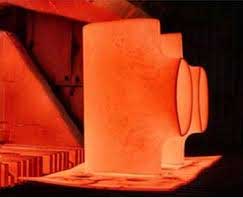

ASTM A234 AS Buttweld Fittings, Low Alloy Steel 90 Degree Elbow and Tee Supplier in Mumbai

We keep huge stock of Chrome Moly Fittings and Alloy Steel Concentric / Eccentric Reducer accordance to ASME B16.9.

What Is Alloy Steel Pipe Fittings?

Alloy steel pipe fittings are versatile components designed possessing a range of alloys. The content of alloy ranges from 1% up to 50%. The higher the content of alloys greater is its corrosion and oxidation resistance properties. The versatile fittings play an important role in determining the characteristics of the flow of fluids and gases across stress-induced environments.

Alloy Steel Short Vs Long Radius Elbow

Elbows are fittings that are employed to change the direction of the flow of fluids and gases. The versatile grade is designed in short or long radius and can be distinguished in certain aspects.

- AS short radius elbow is designed with a radius of curvature that is equal to its outer diameter. An alloy steels long radius elbow has a radius of curvature that is 1.5 times its outer diameter.

- Long radius elbows are used in applications where there is wear and tear in the system. A short radius elbow is preferred in a normal system.

- A short radius alloy steels grade is seen in use in tight areas, while long radius elbows are used in normal working conditions.

Refer Alloy Steel Stub End and SA 234 AS Pipe Cap equivalent, chemical, corrosion allowance and properties

Alloy Steel Tee Vs Lateral Tee

- Alloy steel tee is designed in the shape of a T, while an Alloy steel lateral tee is designed in the shape of a Y.

- A steels tee has two outlets that are opposite to each other, while the branch port is at 90 degrees. In a lateral tee fitting the 2 branch ports are seen in opposite directions. Here the branch port may be at 45 or 60 degrees.

Can You Harden Chrome Moly Fittings?

Chrome fittings are generally hardened by the carburization process. Here the metal absorbs carbon as the metal is heated with carbon-bearing material or charcoal. The fittings are later quenched, which helps in reducing wear and tear.

Does Chrome Moly Pipe Fittings Need To Be Heat Treated?

A chrome moly pipe fitting possesses superior strength and other properties that don’t require the fitting to be heat treated. These fitting can be easily heat treated following work-hardening processes.

Manufacturer of Alloy Steel Buttweld Fittings in various thickness such as Schedule 40 and 80, Supplier of Chromoly Weld/ Seamless AS Equal and Reducing Tee in cut to size

Types of Alloy Steel Pipe Fittings

Alloy Steel Buttweld Fittings

There are many benefits if you buy from ALLoy Steel Pipe Fittings Manufacturers, like high quality, best price and wide range.

Alloy Steel Tee

Check below product AS Tee Manufacturer in India, we use only high quality & tested material to produce Alloy Steel Fittings

Alloy Steel Elbow

Why don't you directly contact a Alloy Steel Pipe Fittings Manufacturer in India? We offer an extensive range of AS Elbow in Mumbai, free sample before dispatch of complete order.

Looking for Low Alloy Steel Fittings manufacturers in India? A wide range of Chrome Moly Buttweld Pipe Fittings at best price in India

4150 Alloy Steel Pipe Fittings Marking

- Products Name: Tee

- Standard : ASME B16.9

- Manufacturer Company Name : P.M. Metal

- Schedule: SCH160

- Grade: ASTM A234 WP11

- Code Of ASTM Material: Alloy Steel

- Heat Number (HN): 23674

- Size In Inch: 3"