1mm, 2mm, 4mm Stainless Steel Stranded Wire and SS Mesh Supplier in Mumbai

What is Stainless Steel Wire?

Stainless steel wires are designed with non-alloy carbon steel. These wires possess a carbon contentbetween 0.4% up to 0.95%. These high strength wires have considerable tensile strength and performance, allowing them to be used in harsh environments. The wires of this grade contain a minimum of 11% chromium content giving the wires aprotective coating. The coating allows the components to possess superior corrosion resistance properties. The wires in this grade have high ductility and are a feature in high temperature and pressure applications.

304 vs 316 Stainless Steel Wire

Stainless steel is made up of two prominent and common grades namely SS 304 and SS 316. These versatile grades are used to manufacture stainless steel wire of different thicknesses and sizes. These grades can be distinguished from key features.

- Stainless steel 304 steel wire is designed with a chemical content of 18% chromium and 8% nickel. 316 stainless steel wire possess a chemical content of 6% chromium, 10-12% nickel, and 2%-3% of molybdenum.

- The content of molybdenum in the 316 stainless steel wires gives these components enhanced pitting and corrosion resistance properties the 304 grade.

- A 304 stainless steel wire is cheaper than SS 316 steel wire.

Is Mig Welding Stainless Steel and magnetic?

The MIG welding process makes use of a solid wire electrode that is heated and fed to a weld pool. A stainless steel austenitic grade is nonmagnetic irrespective of the process. Martensitic and ferritic grades of stainless are magnetic or can turn magnetic after due process.

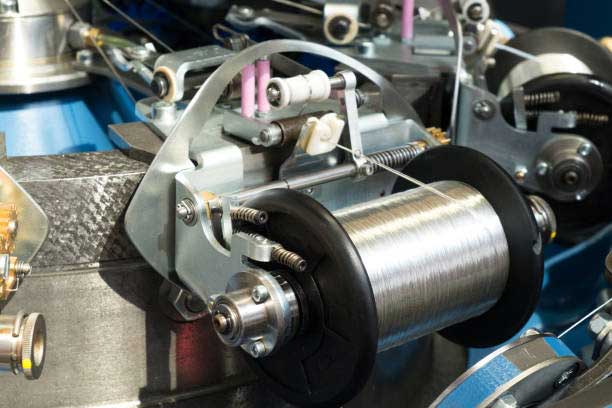

What is Stainless Tie Wire made of Stainless Steel Wire Rod?

A stainless steel wire rod is predominately used to manufacture wires. The semi-finished product can be rolled into tie wires of different sizes and shapes to meet different industrial requirements.

Table of Content

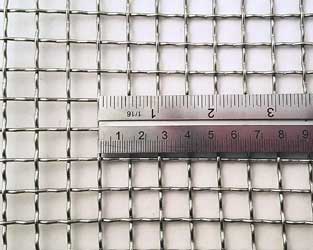

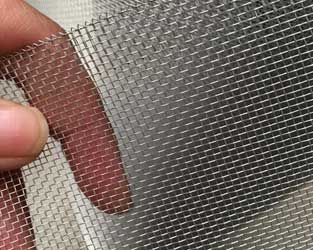

Stainless Steel Wire Mesh Specification

| Specifications | ASTM A313 ASME SA313, ASTM A580 ASME SA580, AMS 5514 |

|---|---|

| Diameter | 0.0004" to 0.040" 10 microns to 1.0 mm Other Sizes on Request |

| Group |

|

| Density | 8.89 g/cm3 |

| Grades | 304L, 304, 316, 17-4PH, 316L |

| Wire Resistance (μΩ.m): | as standard |

| Dimensions | ANSI/AWCI – 01 -1992 and ASTM E 2016-11 and RRW 360 |

| Wire Elongation (≥ %): | 28-30 |

| Length | Cut Lengths: 0.125" to 72" No Limit on Spooled Lengths |

| welded wire mesh | Roll Width: 36inch, 24inch, 1Metre, 72inch, 48inch, or 84inch Roll Length: 100feet or 150feet |

| Ultimate Strength (≥ MPa): | 580-750 |

| wires mesh weaving methods | twill weave, plain weave, dutch weave |

| Surface | Polished bright, Smooth, Bare, Enamel, PTFE, Ceramic, Plated |

| Technique | Cold Rolled, hot rolled |

| Tempers | Tempers range from dead soft annealed to ultra spring temper |

| Wire available in form of | Flat, Filler, Coil, Welding, Electrode, mesh, filter mesh, Knitted wire mesh, mig, spring, tig, stranded and twisted Manufacturer and Supplier |

| Condition | M, Y, 1/2Hard |

| Variour Test Certificates of Stainless Steel Wire Suppliers In India |

|

| Offered in a wide range of packages including: |

|

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Stainless Steel Wire Price Per Kg

Stainless Steel Wire Mesh Price List India, including grades 304/309S/316/316L, are a specialty. Order! Contact us immediately for Ss 304 Wire Mesh Price, customized service, and excellent after-sales support!

| Products | Wire Gauge Number | Min. Tensile Strength | Total Length | Thickness | Feet per Lb. | Price |

|---|---|---|---|---|---|---|

| STAINLESS STEEL WIRE, S.S.WIRE FROM WIREROD GRADE: 430 SIZE: 0.120 I/WE INTEND TO CLAIM REWARDS UNDER MERCHANDISE EXP | 21 | 267,000 psi | 166 ft | 0.0475 in / 1.207mm | 166.0 | $74.67/ each |

| RINGS MADE OF STAINLESS STEEL WIRE 304 GRADE : RINGS MADE OF STAINLESS STEEL WIRE | 22 | 267,000 psi | 150 ft | 0.050 in / 1.270mm | 150.0 | $69.02/ each |

| STAINLESS STEEL WIRE,NON MAGNETICGRADE LH SIZE:3.0,3.5MM | 26 | 258,000 psi | 97 ft | 0.0625 in / 1.588mm | 97.0 | $63.99/ each |

| FLEXIBLE CORRUGATED SS HOSE WITH BRAIDINGS OF SS WIRE-STAINLESS STEEL BELLOWS 2X220MM SS316 (2 PLY) 10 BAR | 258,000 psi | 108 ft | 0.059 in / 1.499mm | 108.0 | $67.14/ each | |

| STAINLESS STEEL WIRE, S.S.WIRE FROM WIREROD GRADE: 430 SIZE: 0.098 I/WE INTEND TO CLAIM REWARDS UNDER MERCHANDISE EXP | 261,000 psi | 124 ft | 0.055 in / 1.397mm | 124.0 | $65.83/ each | |

| STAINLESS STEEL WIRE CLOTH - FORM-ENDLESS DIAGONAL SEAM -MESH:CMAX-45 | 265,000 psi | 144 ft | 0.051 in / 1.295mm | 144.0 | $65.83/ each | |

| WIRE MESH #50 (STAINLESS STEEL) ( FOR PACKING GOODS) | 272,000 psi | 185 ft | 0.045 in / 1.143mm | 185.0 | $74.67/ each | |

| STAINLESS STEEL WIRE (HMI/SS-2016-17/0006-14) (ASL81 SR35A-WRNAP NODXP3.00X2.36 (0.29)XCOIL) | 272,000 psi | 203 ft | 0.043 in / 1.092mm | 203.0 | $80.32/ each |

Types of SS Wire

Stainless Wire Tolerance

| Diameter | Nominal AWG | Hardness | Length | |||

|---|---|---|---|---|---|---|

| µm | in | kPSI | Strength | ft | m | |

| 50.8 | 0.002 | 44 | 90-120 | Annealed | 100 | 30.48 |

| 50.8 | 0.002 | 44 | 215-245 | Full | 100 | 30.48 |

| 50.8 | 0.002 | 44 | 155-185 | Half | 100 | 30.48 |

| 76.2 | 0.003 | 41 | 90-120 | Annealed | 100 | 30.48 |

| 76.2 | 0.003 | 41 | 215-245 | Full | 100 | 30.48 |

| 76.2 | 0.003 | 41 | 155-185 | Half | 100 | 30.48 |

| 127 | 0.005 | 36 | 90-120 | Annealed | 100 | 30.48 |

| 127 | 0.005 | 36 | 215-245 | Full | 100 | 30.48 |

| 127 | 0.005 | 36 | 155-185 | Half | 100 | 30.48 |

| 203.2 | 0.008 | 32 | 90-120 | Annealed | 100 | 30.48 |

| 203.2 | 0.008 | 32 | 215-245 | Full | 100 | 30.48 |

| 203.2 | 0.008 | 32 | 155-185 | Half | 100 | 30.48 |

| 254 | 0.010 | 30 | 90-120 | Annealed | 100 | 30.48 |

| 254 | 0.010 | 30 | 215-245 | Full | 100 | 30.48 |

| 254 | 0.010 | 30 | 155-185 | Half | 100 | 30.48 |

| 508 | 0.020 | 24 | 90-120 | Annealed | 100 | 30.48 |

| 508 | 0.020 | 24 | 215-245 | Full | 100 | 30.48 |

| 508 | 0.020 | 24 | 155-185 | Half | 100 | 30.48 |

Stainless Steel Wire Sizes

| Stainless Steel Wires Mesh Size | Diameter of Stainless Steel Wire Gauge To Mm | ||

|---|---|---|---|

| Sizes in mm | In Inch | Sizes in mm | BWG No. |

| 6.4 | 1/4 | 0.56- 0.71 | BWG24-22 |

| 9.5 | 3/8 | 0.64 - 1.07 | BWG23-19 |

| 12.7 | 1/2 | 0.71 - 1.65 | BWG22-16 |

| 15.9 | 5/8 | 0.81 - 1.65 | BWG21-16 |

| 19.1 | 3/4 | 0.81 - 1.65 | BWG21-16 |

| 25.4x 12.7 | 1 x 1/2 | 0.81 - 1.65 | BWG21-16 |

| 25.4 | 1 | 0.81 - 2.11 | BWG21-14 |

| 38.1 | 1 1/2 | 1.07 - 2.11 | BWG19-14 |

| 25.4 x 50.8 | 1 x 2 | 1.47 - 2.11 | BWG17-14 |

| 50.8 | 2 | 1.65 - 2.77 | BWG16-12 |

| 50.8 to 305 | 2 to 12 | At Request | |

Manufacturer and Supplier of single strand stainless steel wire rope and SS Ribbon wire, Check Stainless Steel 304 Cable Updated price list online

Stainless Steel Wire Gauge Chart

| 16 Gauge Stainless Steel Wire A.S.W |

Weight: Pounds/Foot Iron Steel |

Diameter Inches |

Length Feet/Pound Iron Steel |

Roll Thread |

|---|---|---|---|---|

| 1.0588 1.0420 0.8425 0.6669 |

0.630 0.625 0.562 0.500 |

0.94 0.96 1.19 1.50 |

||

| 7/0 | 0.6405 0.5743 |

0.490 0.464 |

1.56 1.74 |

1/2-20 |

| 6/0 | 0.5694 0.5283 0.5188 0.5094 |

0.462 0.445 0.441 0.437 |

1.76 1.86 1.93 1.96 |

1/2-13 1/2-12 |

| 5/0 | 0.4932 0.4290 |

0.430 0.401 |

2.03 2.33 |

7/16-20 |

| 4/0 | 0.4141 0.3975 0.3751 |

0.394 0.386 0.375 |

2.41 2.52 2.67 |

7/16-14 |

| 3/0 | 0.3496 0.3175 |

0.362 0.345 |

2.86 3.15 |

3/8-24 |

| 2/0 | 0.2923 0.2597 |

0.331 0.312 |

3.42 3.85 |

3/8-16 |

| 1/0 | 0.2498 |

0.306 |

4.00 | |

| 1 | 0.2136 0.1974 |

0.283 0.272 |

4.68 5.07 |

5/16-24 5/16-18 |

| 2 | 0.1831 0.1667 |

0.262 0.250 |

5.46 6.00 |

|

| 3 | 0.1588 0.1387 |

0.244 0.228 |

6.30 7.21 |

1/4-32 |

| 4 | 0.1350 0.1199 |

0.225 0.212 |

7.40 8.34 |

1/4-28 1/4-20 |

| 5 | 0.1143 |

0.207 |

8.75 |

|

| 6 |

0.09834 0.09630 0.09328 0.09229 |

0.192 0.190 0.187 0.186 |

10.17 10.38 10.72 10.84 |

12-28 12-24 |

| 7 |

0.08357 0.07440 |

0.177 0.167 |

11.97 13.44 |

10-32 |

| 8 |

0.07001 0.06829 0.06492 |

0.162 0.160 0.156 |

14.28 14.64 15.40 |

10-24 |

| 9 |

0.05843 0.05532 0.05303 |

0.148 0.144 0.141 |

17.11 18.08 18.86 |

8-36 8-32 |

| 10 | 0.04862 0.04168 |

0.135 0.125 |

20.57 23.99 |

|

| 11 | 0.03841 0.03528 |

0.120 0.115 |

26.03 28.35 |

6-40 6-32 |

| 12 | 0.02941 0.02458 0.02357 |

0.105 0.096 0.094 |

34.00 40.68 42.43 |

5-40 4-48 4-40 |

| 13 |

0.02258 |

0.092 |

44.29 | 4-36 |

| 14 | 0.01707 |

0.080 |

58.57 |

|

| 15 | 0.01383 | 0.072 | 72.31 | |

| 16 | 0.01025 | 0.062 | 97.52 | |

| 17 | 0.007779 | 0.054 | 128.56 | |

| 18 | 0.006146 | 0.048 | 162.70 | |

| 19 | 0.004484 | 0.041 | 223.00 | |

| 20 | 0.003268 | 0.035 | 306.02 |

SS Wire Heat Treatment

| Condition as supplied by Alloy Wire | Time (Hr) | Type | Cooling | Temperature | |

|---|---|---|---|---|---|

| °C | °F | ||||

| Annealed or Spring Temper | 1 | Stress Relieve | Air | 250 | 480 |

Buy directly from 316 Stainless Steel Wire Mesh Manufacturers in india for high quality and better price, View Stainless Steel Welding Electrode Dimension Chart

SS Wire Mesh Grades

| Martensitic | Austenitic |

|---|---|

| 410, S41000 | AL-6XN, N08367 |

| 416, S41600 | 201, S20100 |

| 420, S42000 | 204Cu, S20430 |

| 420lc, S42000 | 301, S30100 |

| 440A, S44002 | 301Si, S30116 |

| Custom 450 , S45000 | 302, S30200 |

| Custom 455, S45500 | 302HQ, S30203 |

| Ferritic | 303, S30300 |

| 303Se, S30323 | |

| 430, S43000 | 304, S30400 |

| 430Li, 43000 | 304V, 30400 |

| 434, S43400 | 304L, S30403 |

| 436 , S43600 | 305, S30500 |

| 444, S44400 | 309, S30908 |

| PH Grades | 310, S31000 |

| 17-7 PH® , S17700 | 310S, S31008 |

| 17-4 PH® , S17400 | 316, S31600 |

| PH 15-7Mo®, S15700 | 316, S31600 |

| A286 , S66286 | 316Ti, S31635 |

| AM350, S35000 | 317, S31700 |

| Duplex Grades | 317L, S31703 |

| Duplex 2304, S32304 | 321, S32100 |

| Duplex 2205, S31803, S32205 | 330, N08330 |

| Duplex 2507, S32750-2 | 347, S34700 |

| Carpenter ®20 CB N08020 | |

| Nitronic® 30, S20400 | |

| Nitronic® 32, S24100 | |

| Nitronic® 33, S24000 | |

| Nitronic® 40, S21904, S21900 | |

| Nitronic® 50, S20910 | |

| Nitronic® 60, S21800 |

Stainless Welding Wire Dimension

| Wires Diameter(mm) | Length(M) | Aperture (mm) |

Weight (Kg) | Mesh |

|---|---|---|---|---|

| 4.00 | 30 | 40 | 142 | 0.58 |

| 4.00 | 30 | 30 | 182 | 0.75 |

| 4.00 | 30 | 25 | 213 | 0.87 |

| 3.2 | 30 | 25 | 141 | 0.87 |

| 3.2 | 30 | 20 | 169 | 1.1 |

| 2.6 | 30 | 20 | 116 | 1.12 |

| 2.6 | 30 | 18 | 127 | 1.23 |

| 2.6 | 30 | 15 | 173 | 1.44 |

| 2.0 | 30 | 15 | 92 | 1.49 |

| 2.0 | 30 | 12 | 110 | 1.8 |

| 2.0 | 30 | 10 | 127 | 2.12 |

| 2.0 | 30 | 8 | 155 | 2.54 |

| 1.8 | 30 | 7 | 149 | 3 |

| 1.8 | 30 | 6 | 161 | 3.25 |

| 1.6 | 30 | 7 | 117 | 3 |

| 1.6 | 30 | 6 | 131 | 3.35 |

| 1.6 | 30 | 5 | 150 | 3.85 |

| 1.6 | 30 | 4 | 176 | 4.5 |

| 1.6 | 30 | 3 | 215 | 5.5 |

| 1.4 | 30 | 6 | 105 | 3.5 |

| 1.4 | 30 | 5 | 120 | 4 |

| 1.4 | 30 | 4 | 140 | 4.7 |

| 1.2 | 30 | 8 | 59 | 2.7 |

| 1.2 | 30 | 7 | 68 | 3.1 |

| 1.2 | 30 | 6 | 77 | 3.5 |

| 1.2 | 30 | 5 | 88 | 4 |

| 1.2 | 30 | 4 | 99 | 4.9 |

| 1.2 | 30 | 3 | 132 | 6 |

| 1.0 | 30 | 6 | 55 | 3.6 |

| 1.0 | 30 | 5 | 65 | 4.25 |

| 1.0 | 30 | 4 | 76 | 5 |

| 1.0 | 30 | 3.2 | 92 | 6 |

| 1.0 | 30 | 3 | 97 | 6.35 |

| 1.0 | 30 | 2.18 | 122 | 8 |

| 0.8 | 30 | 2.83 | 68 | 7 |

| 0.8 | 30 | 2.38 | 78 | 8 |

| 0.8 | 30 | 2.2 | 83 | 8.5 |

| 0.8 | 30 | 2 | 88 | 9 |

| 0.8 | 30 | 1.75 | 98 | 10 |

| 0.8 | 30 | 1.5 | 108 | 11 |

| 0.8 | 30 | 1.3 | 118 | 12 |

| 0.7 | 30 | 1.4 | 90 | 12 |

| 0.7 | 30 | 1.84 | 75 | 10 |

| 0.6 | 30 | 1.21 | 77 | 14 |

| 0.6 | 30 | 1.52 | 66 | 12 |

| 0.6 | 30 | 1.94 | 55 | 10 |

| 0.5 | 30 | 1.3 | 54 | 14 |

| 0.5 | 30 | 1.09 | 61 | 16 |

| 0.5 | 30 | 0.9 | 69 | 18 |

| 0.5 | 30 | 0.77 | 76 | 20 |

SS 304 Wire Mesh Physical Properties

| Condition | Stainless Steel Wire Tensile Strength Chart | Approx. operating temperature | ||

|---|---|---|---|---|

| ksi | N/mm² | °C | °F | |

| Annealed | 87 – 116 | 600 – 800 | -200 to +300 | -330 to +570 |

| Spring Temper | 189 – 319 | 1300 – 2200 | -200 to +300 | -330 to +570 |

304 Stainless Steel Wire Chemical Composition

| Chemical Composition | Key Features | Specifications | Typical Applications | Designations | ||

|---|---|---|---|---|---|---|

| Element | Min % | Max % | Good mechanical properties and corrosion resistance. | ASTM A313 ASTM A580 BS 970 BS 2056 |

Springs. Engineered components. Wire mesh. Wire cloth. Hose braiding. |

W.NR 1.4301 W.NR 1.4307 UNS S30400 AWS 161 |

| S | – | 0.030 | ||||

| C | – | 0.07 | ||||

| Si | – | 1.00 | ||||

| Mn | – | 2.00 | ||||

| Ni | 8.00 | 10.50 | ||||

| P | – | 0.045 | ||||

| Cr | 17.50 | 19.50 | ||||

| Fe | BAL | |||||

SS Rope Mechanical Properties

| Coefficient of Expansion | 18.2 μm/m °C (20 – 100°C) | 10.1 x 10-6 in/in °F (70 – 212°F) |

|---|---|---|

| Density | 8.0 g/cm³ | 0.289 lb/in³ |

| Modulus of Rigidity | 70.3 kN/mm² | 10196 ksi |

| Melting Point | 1454°C | 2650°F |

| Modulus of Elasticity | 187.5 kN/mm² | 27195 ksi |

SS 304L ASTM A580 Wire

- in coil or spool

- soft or hard

- pickled or bright finish

Leading SS 316L Wire Manufacturers In India and 304 Stainless Steel Wire mesh Supplier, Buy 2mm stainless steel 904L wire at best price in Mumbai

Stainless Steel Wire Rope Hs Code

| HS CODES HEADING | |

|---|---|

| Stainless Steel Wire Hs Code Heading | Heading Description |

| 7223 | WIRE OF STAINLESS STEEL |

| HS CODES PRODUCTS | |

| Hs Codes | Products Description |

| 72230091 | Of thickness of above 1.5 mm |

| 722300 | Wire of stainless steel: |

| 72230092 | Of thickness of 0.46 mm and above but not exceeding 1.5 mm |

| 72230010 | Electrode quality |

| 72230099 | Of thickness of below 0.46 mm |

SS 304 Spring Wire Inventory

| Stainless Steel Wire | Stainless Welding Wire |

| Nylon Coated Stainless Steel Wire | Stainless Steel Wire Mesh |

| Stainless Steel Cable | 304 Stainless Steel Wire |

| Stainless Steel Wire Rope | Stainless Steel Welded Wire Mesh |

| Stainless Steel Cable Railing | Stainless Steel Cable Mesh |

| Stainless Steel Mig Wire | Ss Rope |

| Stainless Wire | Stainless Steel Wires |

| Ss Wire | Stainless Steel Wire Grades |

| Ss Mesh | Stainless Steel Insulated Wire |

| Stainless Steel Welding Wire | 316 wires |

| Stainless Mig Wire | Stainless steel ribbon wire |

| Ss Wire Mesh | SS 304 spring wire |

| Stainless Steel Flux Core Wire | Stainless Steel Welding Electrode |

| Ss Wire Rope | Stainless Steel Bright Wire |

| Stainless Steel Tie Wire | Stainless Steel Ultra Fine Wire |

| Stainless Steel Chicken Wire | ss 304 wire mesh |

| Stainless Flux Core Wire | stainless steel stranded wire |

| Stainless Wire Rope | SS 304L ASTM A580 Wire |

SS Mesh Wear-Resistant

| Dia. | Dia. Tolerance | Fabrication | Max. Temperature, °F |

1/4 lb. Spool | 1 lb. Coil | ||||

|---|---|---|---|---|---|---|---|---|---|

| Lg., ft. |

Each | Lg., ft. |

Each | ||||||

| 0.064" | -0.001" to 0.001" | Cold Drawn | 300° | 22 | 6504K44 | 7.47 | 91 | 6504K14 | 24.39 |

| 0.032" | -0.001" to 0.001" | Cold Drawn | 300° | 91 | 6504K41 | $8.51 | 360 | 6504K11 | $28.01 |

| 0.105" | -0.001" to 0.001" | Cold Drawn | 300° | __ | ______ | __ | 34 | 6504K16 | 23.43 |

| 0.04" | -0.001" to 0.001" | Cold Drawn | 300° | 58 | 6504K42 | 8.36 | 230 | 6504K12 | 27.31 |

| 0.08" | -0.001" to 0.001" | Cold Drawn | 300° | __ | ______ | __ | 58 | 6504K15 | 24.14 |

| 0.051" | -0.001" to 0.001" | Cold Drawn | 300° | 35 | 6504K43 | 7.66 | 140 | 6504K13 | 25.01 |

| 0.128" | -0.001" to 0.001" | Cold Drawn | 300° | __ | ______ | __ | 22 | 6504K17 | 23.16 |

Stainless Steel Wire Applications

- Architectural/Civil Engineering

- Transport

- Chemical/Pharmaceutical

- Oil and Gas

- Medical

- Food and Drink

- Water

- General

Searching for

Stainless Steel Wire supplier in your country? Checklist of material we export in the following areas.

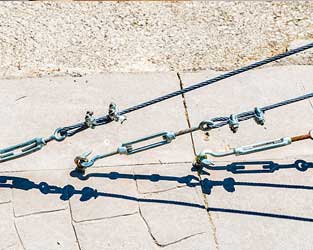

Stainless Steel Wire Rope

Bangladesh, Jakarta -Indonesia, Dubai, Los Alamos -Mexico, Hong Kong, Turkey, Argentina, Germany, China, Oman, Saudi Arabia (KSA).

Stainless Steel Mig Wire

Malaysia, Poland, Romania, Indonesia, Malaysia, Iran, Qatar, New Zealand, Brazil, Netherlands, United Arab Emirates (UAE).

SS Wire Mesh

USA, Chile, Ellington -United States, Canada, Sweden, United States, Greece, Singapore, Vietnam, Mexico, Denmark, Thailand, Finland.

Stainless Steel Cable Mesh

Russia, Belgium, Norway, Egypt, Bahrain, Philippines, South Korea, Peru, Malaysia, Tehran -Iran, Colombia, Italy.

Stainless Steel Ribbon Wire

Spain, Jakarta, Europe, Australia, Jordan, Dammam -KSA, Japan, Istanbul -Turkey, NY 12203 (USA), Dubai -UAE, Kuala Lumpur.

SS 304L ASTM A580 Wire

France, Singapore, Taiwan, South Africa, Portugal, Morocco, Czechia, Kuwait, Austria, United Kingdom (UK), Nigeria.