9th Khetwadi Ln, Girgaon, Mumbai, Maharashtra 400004

ASME SA358 Tp304 Class 1 Tube and ASTM A358 Tp 316 Efw Pipe Supplier in India

Finding Sa358 Welded Pipe suppliers who can supply in custom cut to length sizes? IBR approved ASTM A358 Tp321 ERW Pipe manufacturer and exporter in India.

Difference between ASTM A358 Class 1, Class 2, Class 3, Class 4, Class 5

ASTM A358 grade has 5 classes, each of them have their own set of features and characteristics.

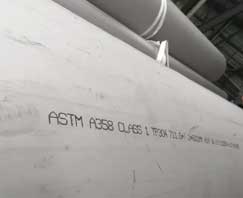

- ASTM A358 Class 1 module is double welded in place using filler metal throughout all the passes. The components are completely radiographed.

- Class 2 piping items are double welded, making use of filler material across all the passes. The grade doesn’t require to be radiographed across the system.

- Class 3 components are single welded in place using a filler material.

- ASTM Class 4 grade is single welded without the requirement of filler metal.

- ASTM A358 Class 5 grade can be double welded using filler material and are spot radiographed.

Check updated A358 Gr 347 Steel Pipe Price per meter in India, View ASTM A358 Material equivalent standard, chemical composition, custom sizes in mm and lengths as per ANSI/ ASME B36.10M.

ASTM A358 EFW Pipe vs A358M EFW Pipe

The ASTM A358 EFW pipe is stated by inch-pound or SI units and is separately regarded as a standard. A358M EFW pipe doesn’t imply the inch-pound units due to the designation of metric standards.

What is ASTM A358 pipe?

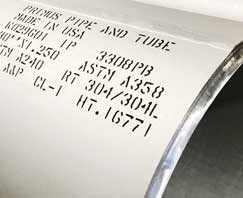

ASTM A358 pipe is an austenitic electric fusion welded stainless steel grade. These pipes are designed with a superior content of chromium and nickel, giving them enhanced corrosion and oxidation resistance properties. The high-strength pipes work in high-temperature systems and can be shaped in precise shapes to be employed in different applications of choice.

We supplies A358 Gr 347 Welded Pipe to Oil & Gas Industry. PED 2014/68/EU and IBR certified SA358 Pipe And ASTM A358 Ss Pipe in India. Large stock of ASTM A358 Grade 304 Class 1 Tube supplier in Mumbai for High Temperature Range and Density.

ASTM A358 pipe vs ASME SA358 pipe

ASTM and ASME are two common standards that are used in manufacturing pipes in the A358 grade. Both these grades are identical and can be distinguished in certain features.

- ASTM A358 pipes belong to an organization that cover s dimensions and standards for technological services in different industries. ASME SA358 pipe is a grade in the piping industry that covers different designs for manufacturing a range of equipment for different pressure vessel equipment.

- ASME covers around 600 standards and codes for a range of technical materials. ASTM grade covers 12,000 or more standards for use in different products and services.

Find your size in our online inventory of ASTM A358 Class 1 Pipe in a variety of dimensions in ASME B36.19. Buy ISMT, Jindal, MSL, Bao steel ASTM A358 Tube and SA358 Gr 347 ERW Pipe at competitive pricing in Mumbai

Types of ASTM A358 Pipe