9th Khetwadi Ln, Girgaon, Mumbai, Maharashtra 400004

ASTM A335 Gr P22 Alloy Steel Seamless Pipe and ASME SA335 P22 Boiler Tube material Supplier in India

Searching SA335 P22 Round Pipe and P22 Pipe suppliers? IBR and KNPC approved manufacturer and distributor of SA 335 gr P22 Seamless Boiler Steel Pipes and Low Alloy ASTM A335 P22 steel Material in Mumbai.

ASTM A335 P22 Pipe Vs ASTM A335 P22 Tube

ASTM A335 P22 pipes and ASTM A335 P22 tubes are near identical materials and can be used interchangeably in the system. Both these piping modules have some differences which set them apart.

- A355 P22 pipes can only be designed in a circular cross-section. Tubes can be designed in circular, square, and rectangular cross-sections.

- Pipes need the requirement of special equipment to be shaped precisely. Tubings in this grade can be easily shaped and bent without any excess wrinkling or distortion.

- A335 P22 tubes are stronger and more rigid in comparison to a pipe in this grade.

- P22 A335 pipes are employed in transporting of fluids and gases, while tubes in this grade are preferred in precision applications like medical devices having an outstanding outer diameter.

Exporter and supplier of P22 Seamless Pipe in India, Chrome-Moly A335 p22 pipe Hardness & Allowable Stress to ensure the right material, Get ASTM A335 P22 IBR Pipe and UNS K21590 Seamless Pipe available in Sch 5 - XXS

ASTM A335 Gr P22 Pipe Vs ASME Sa335 Gr P22 Pipe

ASTM and ASME are two common standards that are employed in manufacturing piping modules in the A355 Gr P22 range. These standards are nearly identical but can be distinguished based on certain key features.

- ASTM A335 Gr P22 pipe belongs to a standard that covers a range of standards, codes, and dimensions for different industries. ASME Sa335 Gr P22 pipe covers designs that are used in the manufacturing of pressure vessel equipment.

- The ASME standard covers nearly 600 codes and standards for different technical materials. ASTM covers around 12,000 or more standards.

What Is Alloy Steel P22 Seamless Pipe

P22 seamless pipe is a module made from a solid sheet of sheet or bar. Hot steel billets are passed through these pipes to effectively shape the pipes in correct alignment. A seamless pipe has higher load-bearing capacity and strength than other standard grades.

What Is P22 Pipe Material Temperature Limit

The Pipes of the P22 grade are used in temperatures up to 590 degrees C. The ability of the material to work at high temperatures allows them to be well suited for use in boiler parts, pressure vessel grades, etc.

Manufacturer and exporter of ASTM A335 P22 Pipe and Tubes, SA 335 gr P22 High Pressure Pipe and ASTM A335 gr P22 High Temperature Seamless Pipe Dimensions and Weights according to ASME B36.19

ASTM A335 P22 and P11 Material

Stockist and Supplier of Alloy Steel P22 Pipe material and sa335p22 Chrome Moly Seamless and Welded Ferritic Alloy-Steel Pipes in India. Best Rates for ASTM A335 P22 Smls Pipe and Ferritic Alloy Steel A335P22 Material in Mumbai

Types of SA 335 Gr P22 High Pressure Pipe

Finding A335 P22 Pipe suppliers in India? Get ASTM A335 P22 Alloy Steel Pipe in Length 3 meter/ 6 meter, Check high Performance SA335 gr P22 Chrome Moly Pipe, Grade P22 Seamless Pipe & SA335P22 Welded Pipe at affortable price.

Sa335P22 Pipe Welding Procedure

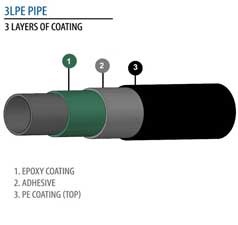

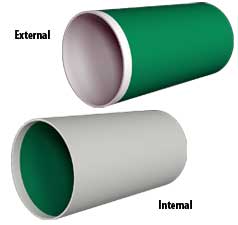

Alloy P22 Pipe Coating Types

3LPE Coated

SA 335 Gr P5 3LPE Coated Pipes

Liquid Epoxy (LE)

ASTM A335 P5 LE Liquid Epoxy Coated Pipe

FBE Coated

ASTM A335 P5 steel FBE Coated Pipe