ASTM A312 Gr TP420 Seamless Pipe and Stainless 420 Steel Welded Tube Suppliers in India

What is Stainless Steel 420 Pipe

Stainless steel 420 pipes belong to a martensitic steel grade containing high carbon content. The pipes in this grade are designed with good chromium content that showcases excellent corrosion resistance in stress-induced environments when they are polished. The versatile grade exhibits a scaling resistance to temperatures up to 650 degrees C. The material has the highest hardness of 50HRC and can be easily machined to precisely shape the components.

What is the difference between ASTM A312 Gr TP420 and ASME SA312 Gr TP420

- ASME SA312 Gr TP420 covers a standard that specifies design codes and standards for different pressure-rated applications. ASTM A312 Gr TP420 covers shapes, sizes, and structural qualities of different piping items.

- ASTM grade has specified 12,000 or more standards, while ASME covers nearly 600 technical standards.

Which is better 420 stainless steel tubing or SS 420 ERW pipe?

Pipes and tubes are two common piping modules employed in the SS 420 grade. These components have some varying characteristics and work optimally well across different systems. An erw pipe of this grade can be employed in connecting large sections in place when compared to a steel tubing of 420 grade. The versatile tubing can be shaped in different shapes and has a higher load-bearing capacity than a pipe.

Stainless Steel 420 Seamless vs Welded Pipe

Seamless and welded pipes are two configurations used to manufacture stainless steel 420 grade. Both these types can be distinguished based on certain features.

- A seamless SS 420 pipe is designed by passing hot steel billets through extruded metal and shaping it precisely. An SS420 welded pipe is manufactured by joining pieces of sheets or strips in the system.

- Seamless pipe modules are stronger and have a higher load-bearing capacity when compared to a welded pipe.

- SS 420 welded pipes are cheaper than standard seamless pipes of the SS 420 grade.

What is ASME SA 312 SUS 420 Round Pipe

ASME SA 312 SUS 420 round pipe is a module designed in seamless or welded configurations. The pipes have a circular cross-sectional area and require specialized material to manufacture them.

Table of Content

Searching Stainless Steel 420 Pipe suppliers in Mumbai? Stockist and distributor of UNS S42000 Seamlss Tubes and ASME SA 312 SUS 420 Round Pipe in India

AISI 420 Pipes Materials Selection And Specification

| Specifications | ASTM/ASME A 312/ SA 312 |

|---|---|

| Size | 1/8″NB to 30″NB IN |

| Dimensions | ASME, ASTM and API |

| Schedule | Schedule20, Schedule30, Schedule40, STD, Schedule80, XS, Schedule60, Schedule80, Schedule120, Schedule140, Schedule160, XXS |

| SS 420 Pipes | 1/2 NB to 16 NB |

| Type | Seamless / ERW / Welded / Fabricated / LSAW Pipes |

| ERW 420 Pipes | 1/2 NB to 24 NB |

| Form | “U” Shape, Custom Pipes, Round Pipes, Hydraulic Pipes |

| EFW 420 Pipes | 6 NB to 100 NB |

| End | Beveled End, Plain End, Treaded |

| Length | Double Random, Single Random, & Cut Length. |

Stainless Steel 420 Welded Pipe Composition Standard

| Grade | S | C | Cr | Mn | MO | Si | Ni | P | CU | |

|---|---|---|---|---|---|---|---|---|---|---|

| 420 | Min | - | - | 12.0 | - | - | - | - | - | - |

| max | 0.03 | 0.15 | 14.0 | 1.00 | - | 1.00 | - | 0.04 | - |

420 Stainless Steel Pipe Mechanical Characteristics

| Grade | Elongation (% in 50mm) min | Yield Strength 0.2% Proof (MPa) min | Tensile Strength (MPa) min | Hardness | |

|---|---|---|---|---|---|

| Rockwell B (HR B) | Brinell (HB) | ||||

| 420 | 25 | 50,000 | 95,000 | - | 175 |

We provide SS 420 ERW Tube and Austenitic Stainless Steel 420 Railing Pipes with instant delivery, 420 SS Schedule 40 Pipe Weight Chart.

420 SS Erw Pipes Physical Properties

| Grade | Elastic Modulus (GPa) | Density (kg/m3) | Mean Coefficient of Thermal Expansion (μm/m/°C) |

Specific Heat 0-100°C (J/kg.K) |

Thermal Conductivity (W/m.K) |

Electrical Resistivity (nΩ.m) | |||

|---|---|---|---|---|---|---|---|---|---|

| 0-315°C | 0-100°C | 0-538°C | at 100°C | at 500°C | |||||

| 420 | 300 | 7900 | 11.8 | 11.5 | 11.9 | 480 | 25.9 | - | 570 |

Stainless Steel 420 Efw Pipes Schedule Chart

| NB Sizes | Schedule 5 | Schedule 10 | Schedule 40 | Schedule 80 | Schedule 160 |

|---|---|---|---|---|---|

| 1 1/4″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1/8″ | ✓ | ✓ | ✓ | ✓ | |

| 2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1/4″ | ✓ | ✓ | ✓ | ✓ | |

| 2 1/2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 3/8″ | ✓ | ✓ | ✓ | ✓ | |

| 3″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1/2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 4″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 3/4″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 6″ | ✓ | ✓ | ✓ | ✓ | |

| 1″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 8″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 1 1/2″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 5″ | ✓ | ✓ | ✓ | ✓ | |

| 14″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 10″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 16″ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 12″ | ✓ | ✓ | ✓ | ✓ | ✓ |

Astm A312 Tp420 Pipes Size Chart In Mm And Inches

| Wall | Sizes ( O.D.) |

|---|---|

| .095 | 1/2 , 5/8 , 1 , 1 1/4 , 1 1/2 , 2″ |

| .010 | 1/16 , 1/8 , 3/16″ |

| .083 | 1/4 , 3/8 , 1/2 , 5/8 , 3/4 , 7/8 , 1 , 1 1/4 , 1 1/2 , 1 5/8 , 1 7/8 , 2 , 2 1/2 ,3″ |

| .020 | 1/16 , 1/8 , 3/16 , 1/4 , 5/16 , 3/8″ |

| .109 | 1/2 , 3/4 , 1 , 1 1/4 , 1 1/2 , 2″ |

| .012 | 1/8″ |

| .120 | 1/2 , 5/8 , 3/4 , 7/8 , 1 , 1 1/4 , 1 1/2 , 2 , 2 1/4 , 2 1/2 , 3″ |

| .016 | 1/8 , 3/16″ |

| .028 | 1/8 , 3/16 , 1/4 , 5/16 , 3/8 , 1/2 , 3/4 , 1 , 1 1/2 , 2″ |

| .125 | 3/4 , 1 , 1 1/4 , 1 1/2 , 2 , 3 , 3 1/4″ |

| .035 | 1/8 , 3/16 , 1/4 , 5/16 , 3/8 , 7/16 , 1/2 , 16 , 5/8 , 3/4 , 7/8 , 1 , 1 1/4 , 1 1/2 , 1 5/8 , 2 , 2 1/4″ |

| .134 | 1″ |

| .049 | 3/16 , 1/4 , 5/16 , 3/8 , 1/2 , 16 , 5/8 , 3/4 , 7/8 , 1 , 1 1/8 , 1 1/4 , 1 1/2 , 1 5/8 , 2 , 2 1/4″ |

| .375 | 3 1/2″ |

| .065 | 1/4 , 5/16 , 3/8 , 1/2 , 16 , 5/8 , 3/4 , 7/8 , 1 , 1 1/4 , 1 1/2 , 1 5/8 , 1 3/4 , 2 , 2 1/2 , 3″ |

| .250 | 3″ |

1.4021 Pipes Equivalent Grades

| STANDARD | JIS | WERKSTOFF NR. | BS | UNS | EN |

|---|---|---|---|---|---|

| SS 420 | SUS 420J1 | 1.4021 | 420S29 | S42000 | X20Cr13 |

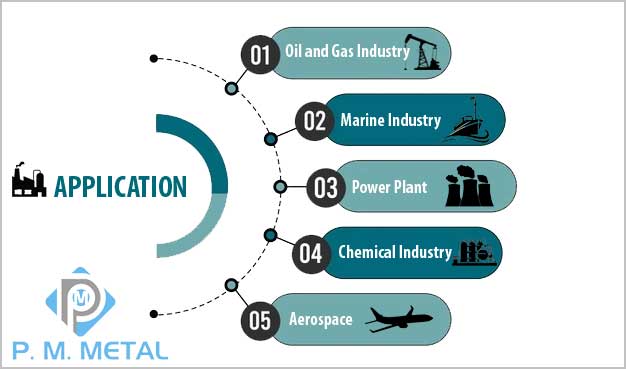

Stainless Steel 420 Seamless Pipe Applications

Types of UNS S42000 Pipe

Super Ferritic Stainless Steel 420 Capillary Tubing and ASTM A312 TP 420 Round Tube stockist in Mumbai, call us now for SS Grade 1.4021 Polished Pipe a free sample.

Stainless Steel 420 Pipe Weight Per Foot Chart

| Nominal size [inches] | Outside diameter [inches] | Outside diameter [mm] | Weight [lb/ft] | Weight [kg/m] | Wall thickness [inches] | Wall thickness [mm] |

|---|---|---|---|---|---|---|

| 16 | 16,000 | 406,4 | 192,43 | 286,64 | 1,219 | 30,96 |

| 4 | 4,500 | 114,3 | 19,00 | 28,32 | 0,438 | 11,13 |

| 14 | 14,000 | 355,6 | 150,79 | 224,65 | 1,094 | 27,79 |

| 5 | 5,563 | 141,3 | 27,04 | 40,28 | 0,500 | 12,7 |

| 20 | 20,000 | 508,0 | 296,37 | 441,49 | 1,500 | 38,10 |

| 6 | 6,625 | 168,3 | 36,39 | 54,20 | 0,562 | 14,27 |

| 22 | 22,000 | 559,0 | 353,61 | 527,02 | 1,625 | 41,28 |

| 8 | 8,625 | 219,1 | 60,71 | 90,44 | 0,719 | 18,26 |

| 24 | 24,000 | 610,0 | 429,39 | 640,03 | 1,812 | 46,02 |

| 10 | 10,750 | 273,0 | 89,29 | 133,06 | 0,844 | 21,44 |

| 18 | 18,000 | 457,0 | 244,14 | 363,56 | 1,375 | 34,93 |

| 12 | 12,750 | 323,8 | 125,49 | 186,97 | 1,000 | 25,4 |

Ss 420 Pipe Dimension

| Pipe Size (in) |

Nominal Thickness (in) mm |

Diameter (in) mm |

Volume (ft3/ft) |

Transverse Areas (in2) mm2 |

Length of Pipe (ft per sq. foot of surface) |

Number of Threads per inch of Screw | Weight | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| External | Internal | External | Steel | Internal | External Surface (ft) |

Internal Surface (ft) |

(lb/ft) | (kg/m) | ||||

| 5 | 0.26 | 5.563 | 5.05 | 0.1389 | 24.30 | 4.30 | 20.00 | 0.69 | 0.76 | 8 | 14.61 | 21.74 |

| 1/8 | 0.07 | 0.405 | 0.27 | 0.0004 | 0.13 | 0.07 | 0.06 | 9.43 | 14.20 | 27 | 0.24 | 0.36 |

| 4 | 0.24 | 4.500 | 4.03 | 0.0884 | 15.90 | 3.17 | 12.73 | 0.85 | 0.95 | 8 | 10.79 | 16.06 |

| ¼ | 0.09 | 0.540 | 0.36 | 0.0007 | 0.23 | 0.13 | 0.10 | 7.07 | 10.49 | 18 | 0.42 | 0.63 |

| 8 | 0.32 | 8.625 | 7.98 | 0.3552 | 58.42 | 8.40 | 50.02 | 0.44 | 0.48 | 8 | 28.55 | 42.49 |

| 3/8 | 0.09 | 0.675 | 0.49 | 0.0013 | 0.36 | 0.17 | 0.19 | 5.66 | 7.75 | 18 | 0.57 | 0.84 |

| 10 | 0.37 | 10.750 | 10.02 | 0.5476 | 90.76 | 11.90 | 78.85 | 0.36 | 0.38 | 8 | 40.48 | 60.24 |

| ½ | 0.11 | 0.840 | 0.62 | 0.0021 | 0.55 | 0.25 | 0.30 | 4.55 | 6.14 | 14 | 0.85 | 1.26 |

| 12 | 0.41 | 12.750 | 11.94 | 0.7763 | 127.64 | 15.74 | 111.90 | 0.30 | 0.32 | 8 | 53.60 | 79.77 |

| ¾ | 0.11 | 1.050 | 0.82 | 0.0037 | 0.87 | 0.33 | 0.53 | 3.64 | 4.64 | 14 | 1.13 | 1.68 |

| 6 | 0.28 | 6.625 | 6.07 | 0.2006 | 34.47 | 5.58 | 28.89 | 0.58 | 0.63 | 8 | 18.97 | 28.23 |

| 1 | 0.13 | 1.315 | 1.05 | 0.0060 | 1.36 | 0.49 | 0.86 | 2.90 | 3.64 | 11 ½ | 1.68 | 2.50 |

| 16 | 0.50 | 16.000 | 15.00 | 1.2230 | 201.05 | 24.35 | 176.70 | 0.24 | 0.25 | 8 | 78.00 | 116.08 |

| 1 ¼ | 0.14 | 1.660 | 1.38 | 0.0104 | 2.16 | 0.67 | 1.50 | 2.30 | 2.77 | 11 ½ | 2.27 | 3.38 |

| 14 | 0.44 | 14.000 | 13.13 | 0.9354 | 153.94 | 18.64 | 135.30 | 0.27 | 0.28 | 8 | 63.00 | 93.75 |

| 1 ½ | 0.15 | 1.900 | 1.61 | 0.0141 | 2.84 | 0.80 | 2.04 | 2.01 | 2.37 | 11 ½ | 2.72 | 4.04 |

| 18 | 0.56 | 18.000 | 16.88 | 1.5550 | 254.85 | 30.85 | 224.00 | 0.21 | 0.23 | 8 | 105.00 | 156.26 |

| 2 | 0.15 | 2.375 | 2.07 | 0.0233 | 4.43 | 1.08 | 3.36 | 1.61 | 1.85 | 11 ½ | 3.65 | 5.43 |

| 20 | 0.59 | 20.000 | 18.81 | 1.9260 | 314.15 | 36.15 | 278.00 | 0.19 | 0.20 | 8 | 123.00 | 183.05 |

| 2 ½ | 0.20 | 2.875 | 2.47 | 0.0333 | 6.49 | 1.70 | 4.79 | 1.33 | 1.55 | 8 | 5.79 | 8.62 |

| 24 | 0.69 | 24.000 | 22.63 | 2.7930 | 452.40 | 50.30 | 402.10 | 0.16 | 0.17 | 8 | 171.00 | 254.48 |

| 3 | 0.22 | 3.500 | 3.07 | 0.0513 | 9.62 | 2.23 | 7.39 | 1.09 | 1.25 | 8 | 7.58 | 11.27 |

| 3 ½ | 0.23 | 4.000 | 3.55 | 0.0687 | 12.56 | 2.68 | 9.89 | 0.95 | 1.08 | 8 | 9.11 | 13.56 |

Stainless Steel 420 Thick Wall Pipe Pressure Rating

| SS Pipe Size(inches) | SS Pipe Schedule | Temperature(F) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 100 | 200 | 300 | 400 | 500 | 600 | 650 | 700 | 750 | ||

| 1 1/2″ | 40 | 2257 | 1947 | 1750 | 1608 | 1496 | 1425 | 1383 | 1354 | 1340 |

| 80 | 3182 | 2744 | 2466 | 2267 | 2108 | 2009 | 1949 | 1909 | 1889 | |

| 160 | 4619 | 3984 | 3580 | 3291 | 3060 | 2916 | 2829 | 2772 | 2743 | |

| 1″ | 40 | 3048 | 2629 | 2362 | 2171 | 2019 | 1924 | 1867 | 1824 | 1810 |

| 80 | 4213 | 3634 | 3265 | 3002 | 2791 | 2659 | 2580 | 2528 | 2501 | |

| 160 | 6140 | 5296 | 4759 | 4375 | 4068 | 3876 | 3761 | 3684 | 3646 | |

| 2″ | 40 | 1902 | 1640 | 1474 | 1355 | 1260 | 1201 | 1165 | 1141 | 1129 |

| 80 | 2747 | 2369 | 2129 | 1957 | 1820 | 1734 | 1682 | 1648 | 1631 | |

| 160 | 4499 | 3880 | 3486 | 3205 | 2980 | 2840 | 2755 | 2699 | 2671 | |

| 4″ | 40 | 1531 | 1321 | 1187 | 1091 | 1014 | 967 | 938 | 919 | 909 |

| 80 | 2213 | 1909 | 1715 | 1577 | 1466 | 1397 | 1355 | 1328 | 1314 | |

| 160 | 3601 | 3106 | 2791 | 2566 | 2386 | 2273 | 2206 | 2161 | 2138 | |

| 3″ | 40 | 1806 | 1558 | 1400 | 1287 | 1196 | 1140 | 1106 | 1084 | 1072 |

| 80 | 2553 | 2202 | 1979 | 1819 | 1691 | 1612 | 1564 | 1532 | 1516 | |

| 160 | 3840 | 3312 | 2976 | 2736 | 2544 | 2424 | 2352 | 2304 | 2280 | |

| 6 | 40 | 1219 | 1052 | 945 | 869 | 808 | 770 | 747 | 732 | 724 |

| 80 | 1913 | 1650 | 1483 | 1363 | 1267 | 1208 | 1172 | 1148 | 1136 | |

| 160 | 3289 | 2836 | 2549 | 2343 | 2179 | 2076 | 2014 | 1973 | 1953 | |

| 10″ | 40 | 974 | 840 | 755 | 694 | 645 | 615 | 596 | 584 | 578 |

| 80 | 1609 | 1388 | 1247 | 1147 | 1066 | 1016 | 986 | 966 | 56 | |

| 160 | 3147 | 2714 | 2439 | 2242 | 2085 | 1986 | 1927 | 1880 | 1868 | |

| 5″ | 40 | 1342 | 1158 | 1040 | 956 | 889 | 847 | 822 | 805 | 797 |

| 80 | 1981 | 1709 | 1535 | 1411 | 1312 | 1250 | 1213 | 1189 | 1176 | |

| 160 | 3414 | 2945 | 2646 | 2433 | 2262 | 2155 | 2091 | 2049 | 2027 | |

| 8″ | 40 | 1073 | 926 | 832 | 765 | 711 | 678 | 657 | 644 | 637 |

| 80 | 1692 | 1459 | 1311 | 1205 | 1121 | 1068 | 1036 | 1015 | 1005 | |

| 160 | 3175 | 2738 | 2460 | 2262 | 2103 | 2004 | 1944 | 1905 | 1885 | |

Stainless Steel 420 Pipes Finish

View SS UNS S42000 Welded Pipe and ASME SA 312 Tp 420 Condenser Tubes sizes chart in mm. Check Our Global Sales Network For DIN 1.4021 Tubing.

420 SS Pipes Tolerance

| SS 420 Pipe OD | AISI 420 Seamless Pipe Tolerance |

|---|---|

| 4 to 35mm | +/- 0.08mm |

| 35 to 38mm | +/- 0.15mm |

| 38 to 60mm | +/- 0.20mm |

| 60 and above | +/- 0.25mm |

Buy SS 420 Pipe Surface Finish

| Surface features | Surface roughness (Ra) value | Examples of processing methods |

|---|---|---|

| Dark glossy surface | Ra0.2, Ra0.1, Ra0.05 | Grinding, honing, super-fine grinding, polishing |

| Clearly visible knife marks | Ra100, Ra50, Ra25 | Rough turning, rough planing, rough milling, drilling |

| No visible processing marks | Ra1.6, Ra0.8, Ra0.4 | Fine turning, fine grinding, fine hinge, grinding |

| Slightly seen knife marks | Ra12.5, Ra6.3, Ra3.2 | Fine turning, fine planing, fine milling, rough hinge, rough grinding |

420 SS Thin Wall Pipe Packaging

SUS 420 Hollow Pipe Testing

- Hardness Test

- Intergranular Corrosion (IGC) Test

- Mechanical Testing Such as Tensile of Area

- Positive Material Identification – PMI Testing

- Chemical Analysis – Spectro Analysis

- Micro and MacroTest

- Flattening Test

- Flaring Test

- Pitting Resistance Test

Manufacturer of ASME SA 312 AISI 420 Stainless Steel Tube in Mumbai, check our SA 312 TP 420 ERW Pipe online inventory, Exporter of Sanyo Special Steel Japan, Sumitomo, Dmv, and Jindal Stainless Steel 420 Pipe at dealer price in India.

ASME Sa312 Tp420 Welded Pipes Available Type Price

AISI ASTM 420 cold rolled 8k mirror polished hairline satin

Stainless Steel tube Customized Size 4 Inches SS 420 Stainless Steel

ASTM SMLS 420 Stainless Steel Pipe / Stainless Steel Tube

SUS420J1 ASTM 420 UNS S42000 STS420J1 1.4021 20Cr13 AS 420

Prompt Delivery 3mm Wall Thick AISI ASTM A312 420 Seamless Welded

hot sale 2mm 3mm 4mm thick 420 polished stainless steel pipe tube

420 Stainless Steel Pipe Inventory

| AISI 420 Pipes | SS UNS S42000 Welded Pipes |

| Stainless Steel 420 Welded Pipes | ASME SA 312 Tp 420 Condenser Tubes |

| 420 Stainless Steel Pipes | DIN 1.4021 Tubing |

| 420 SS Erw Pipes | ASME SA 312 AISI 420 Stainless Steel Pipe |

| Stainless Steel 420 Efw Pipes | SA 312 TP 420 ERW Pipes |

| Astm A312 Tp420 Pipes | 420 SS Thin Wall Pipes |

| 1.4021 Pipes | Sus 420 Hollow Pipes |

| Stainless Steel 420 Seamless Pipes | Asme Sa312 Tp420 Welded Pipes |

| Uns S42000 Pipes | Ss 420 Industrial Pipes |

| Stainless Steel 420 Pipes | SS 420 Seamless Pipes |

| Ss 420 Pipes | S42000 Steel Welded Pipes |

| Stainless Steel 420 Thick Wall Pipes | 420 SS Seamless Tubes |

| Stainless Steel 420 Pipes | DIN 1.4021 Steel 420 Welded Tube |

| 420 SS Pipes | 420 Nssmc Original Stainless Pipes |

| Buy SS 420 Pipes | S42000 Stainless Steel Round Pipes |

| ASTM A312 Gr TP420 Seamless Pipes | Steel 420 EFW Pipes |

| 420 Stainless Steel Welded Tube | SS 420 Tubes |

| ASME B36.19 UNS S42000 Schedule 40 Pipes | Steel 420 Round Pipes |

| ASME SA 312 SUS 420 Round Pipes | Stainless Steel 420 Seamless Pipes |

| SS 420 ERW Pipes | SS 420 Hollow Tubes |

| Austenitic Stainless Steel Railing Pipes | SS S42000 Pipes |

| 420 SS Schedule 40 Pipes | SS 420 Tubacex Original Stainless Pipes |

| Stainless Steel 420 Capillary Tubing | DIN 1.4021 Steel 420 Fabricated Welded Pipes |

| ASTM A312 TP 420 Round Pipes | SS Grade 1.4021 Polished Pipes |

Are you

looking for a Stainless Steel 420 Pipe Supplier who has a strong network? check our export destinations:

AISI 420 Pipes

Bangladesh, Jakarta -Indonesia, Dubai, Los Alamos -Mexico, Hong Kong, Turkey, Argentina, Germany, China, Oman, Saudi Arabia (KSA).

Stainless Steel 420 Welded Pipe

Malaysia, Poland, Romania, Indonesia, Malaysia, Iran, Qatar, New Zealand, Brazil, Netherlands, United Arab Emirates (UAE).

Stainless Steel 420 Seamless Pipe

USA, Chile, Ellington -United States, Canada, Sweden, United States, Greece, Singapore, Vietnam, Mexico, Denmark, Thailand, Finland.

ASME B36.19 UNS S42000 Schedule 40 Pipe

Russia, Belgium, Norway, Egypt, Bahrain, Philippines, South Korea, Peru, Malaysia, Tehran -Iran, Colombia, Italy.

ASTM A312 TP 420 Round Pipe

Spain, Jakarta, Europe, Australia, Jordan, Dammam -KSA, Japan, Istanbul -Turkey, NY 12203 (USA), Dubai -UAE, Kuala Lumpur.

SS 420 Tubes

France, Singapore, Taiwan, South Africa, Portugal, Morocco, Czechia, Kuwait, Austria, United Kingdom (UK), Nigeria.