9th Khetwadi Ln, Girgaon, Mumbai, Maharashtra 400004

ASTM B167 UNS N06600 Seamless Pipe and Alloy 600 Tube Supplier in India

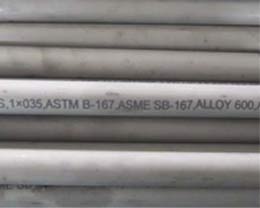

Searching for Inconel 600 Pipe suppliers who supply cut-to-size facilities? We Stock and supply AMS 5580 ASTM B167 UNS N06600 Welded Pipe, Alloy 600 ERW Pipe used for heat exchangers and boiler feeders with Mill Test Certificate EN 10204/3.1B in India

Inconel 600 Pipe Vs Tube

Pipes and tubes are common piping configurations in the Inconel 600 grade. These versatile components can be readily distinguished based on certain features.

- Inconel 600 Tubes are stronger and more robust than pipes of this grade.

- Tubes are available in boiler, condenser, coiled, seamless, and ERW grades. Similarly, pipes can be availed in seamless, ERW, and welded configurations.

- A tubing grade is measured based on their outer diameter and wall thickness. Similarly, a pipe can be identified by a nominal diameter and schedule.

- Alloy 600 tubes can be processed in hot and cold rolling procedures. Inconel 600 pipes can only be processed by the hot rolling process.

- Alloy 600 pipes can accommodate large diameter pipes, while the latter is preferably used in small diameter applications.

Distributor and Stockist of ASME SB 167 UNS N06600 Hot Finished Pipe and Alloy 600 Seamless Pipe in all sizes and thicknesses, Know more about DIN 17742 Inconel 600 Clad Pipe and Cold Drawn Annealed Inconel 600 Seamless Pipe specifications and standards.

What Is ASTM B167 UNS N06600 Pipe?

ASTM B167 UNS N06600 pipe is nickel-chromium grade. The versatile pipes perform well across different corrosive and oxidative media. The outstanding pipe grades showcases enhanced resistance against chloride stress-corrosion cracking in different environments. These UNS NO6600 pipes can withstand cryogenic and high temperature systems and can be easily welded in place following standard welding procedures.

Wide stock of ASTM B829 600 Inconel Exhaust Pipe manufacturers in India, Get complete information of SCH40 Inconel 600 Pipe, Annealed/ Cold Drawn Alloy 600 Seamless Tube and UNS N06600 Square Pipe in custom length, get a free quote now!

What Is the Hardness of Inconel 600 Seamless Pipe?

A seamless pipe of the Inconel 600 grade is designed with a hardness of between 65 to 85 Rockwell.

Supplier and distributor of WERKSTOFF NR. 2.4816 Hexagonal Pipe, ASTM B167 UNS N06600 Pipe and 2.4816 Alloy 600 Square Tubing as per American Standards including ASTM B167, B516, B517, B829, B163, B775, B751 and AMS 5580, View ASTM B167 UNS N06600 Pipe Wall Thickness and Weight Chart in detail.

Alloy 600 tube application

Alloy 600 tubes are high-strength modules designed for use in different systems. The tubes are a common feature in:

- Aerospace components

- Chemical processing systems: chlorination equipment, titanium dioxide, sodium sulfide.

- Petrochemical processing for catalyst regenerators

- Food processing

- Pulp and paper systems

- Thermal processing of roller hearths, vacuum furnace components, nitriding containers, etc.

- Power generation systems- nuclear components.

Get stock of Hot Finished Inconel 600 Pipe according to ASTM B167/B517. Buy ASTM B167 600 Inconel Pipe, ASME SB 167 UNS N06600 Hot Finished Pipe in various shape like Square, Rectangular & Round at affordable price in india.

Different Inconel N06600 Pipe Types