9th Khetwadi Ln, Girgaon, Mumbai, Maharashtra 400004

Alloy C276 Elbow and Hastelloy Fittings manufacturer in India

Manufacturer and Supplier of Hastelloy Pipe Fittings in all types, size and dimension, buy DIN 2.4819 End Cap, Tee and Long/ Short Radius Elbow at affortable price in India

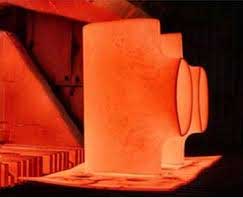

What is Hastelloy C276 Pipe Fittings?

Hastelloy C276 is a grade of superalloys designed with an excellent chemical content of nickel, chromium, and molybdenum. The superior content coupled with tungsten as the stabilizing agent gives the grade excellent corrosion and oxidation resistance properties. The alloy C276 fittings showcase outstanding resistance to pitting and crevice corrosion across different stress-induced environments. The robust fittings of this grade play an important role in influencing the characteristics of the flow across different piping applications. The C276 Hastelloy pipe fittings can be readily welded in place following standard welding procedures.

Contact directly a Hastelloy Pipe Fittings manufacturer in India for factory price and custom sizes, Supplier of Nickel Alloy C276 Stub End and Pipe Cap according to ASME B16.9 standards, Check Dimension of ASTM B366 N10276 Pipe Reducer

Alloy C276 Threaded Pipe Fittings Vs UNS N10276 Socket Weld Fittings

- Alloy C276 threaded pipe fitting is made with threads that correspond to subsequent pipe modules. UNS N10276 socket weld fittings are a pipe attachment detail that has a recessed area where the fitting is connected.

- A socket weld fitting is welded to a subsequent module with a single fillet weld. A threaded fitting has threads that fits directly on the other piping grade.

- Socket weld fittings ensure a permanent, long-lasting fit. Threaded pipe fittings can be easily dismantled and removed.

- A threaded pipe fitting is preferred in low-pressure systems where the load on the system is less. Alloy C276 socket weld fittings are used in high pressure applications.

Get Hastelloy Fittings manufacturers for specific design, We offer custom size ASTM B366 UNS N10276 Reducing Tee and WPHC276 Eccentric Reducer in India, Stockist of Hastelloy Tube Fittings and Ferrule Tee for leak-free connections, best price of Alloy C-276 instrumentation fittings in Mumbai

Nickel C276 Elbow Vs ASTM B366 Alloy C276 Reducer

Elbows and reducers are two common and versatile grades of pipe fittings the Hastelloy C276 grade. The range of fittings are characterized by different functions.

- A nickel C276 elbow is used to change the direction of flow across different units in the piping industry. They are designed in long or short radii and can be bent in different directions.

- ASTM B366 alloy C276 reducer is used to join piping components of different sizes in the system. A reducer is designed in eccentric or concentric types.

How To Weld DIN 2.4819 Reducing Tee?

A DIN 2.4819 reducing tee is generally welded following a gas tungsten arc welding process. Here the tee can be fillet, socket welded or butt welded in place securely.

Butt welded SCH40 Hastelloy UNS N10276 Long/ Short Radius Elbow and Nickel Alloy C276 Stub End manufacturer in India, We supply DIN 2.4819 Return Bends and Hastelloy Alloy 45/ 90/ 180 Degree Elbow with mechanical performance testing

Types of Hastelloy C276 Pipe Fittings

Hastelloy C276 Elbow

Why don't you directly contact a ASTM B366 UNS N10276 Elbow Manufacturer in India? We offer an extensive range of C276 Buttweld Pipe Elbow in Mumbai, free sample before dispatch of complete order.

Check and compare our quality and pricing with any Hastelloy Fittings manufacturers in India, C276 Hastelloy Equal/ Unequal Tee and Nickel C276 Pipe Fittings supplier in Mumbai offer Technical Inspection & MTR Certificate with all delivery

Hastelloy C276 Buttweld Fittings

There are many benefits if you buy from Alloy C276 Buttweld Fitting Manufacturers, like high quality, best price and wide range.

Hastelloy C276 Tee

Check below product ANSI B16.9 Hastelloy C276 Tee Manufacturer in India, we use only high quality & tested material to produce C276 Alloy Equal Tee