9th Khetwadi Ln, Girgaon, Mumbai, Maharashtra 400004

ASME SA 335 Gr P91 Seamless Pipe and UNS K91560 Chrome Pipe Supplier in India

Looking for ASME SA 335 P91 Chrome Tube and P91 Pipe suppliers? Manufacturer and exporter of SA 335 gr p91 SMLS Schedule 40 Pipe, Buy ASTM A335 P91 Alloy Steel Pipe and NBR 5603 P91 High Pressure Pipe in Mumbai.

ASTM A335 P91 Pipe Vs ASTM A335 P91 Tube

ASTM A335 P91 pipes and tubes are common piping modules that are used interchangeably as per the requirements in the system. The items can be distinguished from each other based on certain key aspects.

- A335 P91 pipes are always designed in a circular cross-section. Tubes in this grade can be designed in circular, rectangular, and square cross-sections.

- P91 tubes are stronger and more robust than P91 pipes.

- P91 A335 tubes can be hot and cold rolled. A335 P91 pipes are precisely hot rolled in place.

- Pipes are designed to accommodate larger applications, while tubes are designed to work well with smaller diameter applications.

Manufacturer and supplier of SA335p91 chrome moly alloy pipes as per ANSI/ASME B36.10M, Check SA335P91 Boiler Steel Pipe specification, and get SA335 gr P91 High Temperature Seamless Pipe in custom cut to required lengths.

What Is A335 P91 Material and Sa335 P91 Material

A335/Sa335 P91 material is part of a ferritic alloy steel grade. These items within this range possess high strength that don’t deteriorate with time. The chrome moly grade possesses superior corrosion resistance properties allowing the material within this grade to have excellent performance in stress-induced environments. The chemical content also allows these modules to showcase enhanced resistance to oxidation at elevated temperatures. The versatile grade also exhibits good creep strength and inhibits pitting in marine environments.

Distributor & stockist of P91 Seamless Pipe and ASTM A335 gr P91 Round Pipe, Get details of SA335 P91 IBR Pipe according to Military Specifications. KNPC and Saudi Aramco approved supplier of SA335 p91 material in India.

How Do You Weld a P91 Chrome Pipe?

P91 grade is a high-cost grade material that presents some challenges in the welding process. The P91 chrome pipe is produced by preheating the joint at temperatures between 400 to 500 degrees F. This eliminates any moisture and reduces hydrogen content to eliminate embrittlement caused after finishing the weld. To weld, the metal low-hydrogen filler material is utilized, and the module is welded in place by maintaining the correct temperatures. The material can be controlled cooled and stress relieved to restore the ductility of the grade.

Most popular types of NBR 5603 P91 High Pressure Pipe

Exporter and supplier of SA 335 P91 Alloy Steel Smls Pipe and P91 Pipe, check Ferritic Alloy Steel ASTM A335 P91 Pipe Wall Thickness & Temperature Limit. View standard SA335 P91 Welded Pipe length in meter and sizes chart

AS P91 Pipe Welding Procedure

We can supply P91 Chrome Moly Pipe and ASTM A335 gr P91 Seamless Pipe according to ASME B36.10 and B36.19, get price list of ASTM A335 P91 Material and A335 P91 High Pressure Pipe suppliers in Mumbai

Seamless Ferritic Alloy-Steel P11 Pipe Coating Types

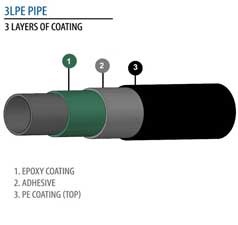

3LPE Coated

SA 335 Gr P5 3LPE Coated Pipes

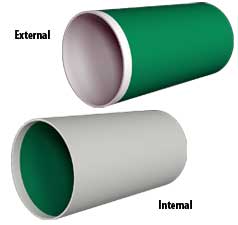

Liquid Epoxy (LE)

ASTM A335 P5 LE Liquid Epoxy Coated Pipe

FBE Coated