9th Khetwadi Ln, Girgaon, Mumbai, Maharashtra 400004

SA 335 gr P9 Seamless Pipe and Alloy Steel UNS S50400 Chrome Pipe Material supplier in Mumbai, India

High quality durable alloy steel ASTM A335 P9 Pipe and check ANSI/ ASME B36.10M SA335 gr P9 High Pressure Boiler Pipe and A335 gr P9 IBR Pipe composition, mechanical, and weight chart

What Is ASTM A335 P9 Pipe and ASTM A335 P9 Tube

Pipes and tubes are key features in the ASTM A335 P9 grade. Both these piping modules can be differentiated from each other based on certain important aspects.

- ASTM A335 P9 Pipe is a device that can only be shaped in a circular cross-section. Tubes can be manufactured in square, rectangular and circular cross-sections.

- A335 P9 pipes can be only hot rolled. The grade of the ASTM A335 P9 tube can be both hot and cold rolled.

- The pipes in this grade are utilized in large diameter applications, whereas tubes are generally preferred in smaller diameter applications.

- A standard pipe grade in the ASTM A335 P9 grade requires special equipment to be shaped. Tubes in this range don’t necessarily require special equipment and can be shaped or bent easily.

- Tubing components are far stronger and more robust than standard pipes in this grade.

Finding Low Alloy ASTM A335 P9 Pipe suppliers who can deliver within a week? Manufacturer and exporter of SA 335 P9 material and ASTM A335 P9 Alloy Steel Seamless Pipe as per ANSI / ASME B36.10M in India

Heat treatment of a335 p9

Heat treatment of the a335 p9 grade is performed by normalizing and tempering the grade at temperatures at 675 degrees C followed by cooling. For tempering, it is expected to heat the components at least by 50 degrees C. The process helps in improving the overall quality and strength of the modules within this grade.

What Is A335 P9 Material?

A335 P9 material is a seamless ferritic alloy grade that is a module of choice in high-temperature applications. Designed with a key composition consisting of chromium and molybdenum these components showcase enhanced corrosion and oxidation resistance properties. The versatile grade has excellent strength and enhanced mechanical performance across stress-induced environments.

Stockist & distributor of SA335 P9 Round Pipe and SA335P9 Seamless Pipe in Mumbai, Before you buy check A335 gr P9 Boiler Steel Pipe and Low Alloy ASTM A335 P9 Pipe Yield Strength, Allowable Stress and Hardness

Basic Types Of ASTM A335 P9 Steel Seamless Pipe

Searching KNPC approve Ferritic Alloy Steel SA 335 P9 Chrome Pipe suppliers for oil and gas pipeline transmissions? Check ASTM A335 grade P9 Alloy Pipe and ASTM A335 P9 Alloy Steel Pipe Dimensions

P9 Pipe Welding Procedure

Exporter & supplier of Alloy Steel A335 P9 Boiler Pipe and Steel Grade P9 Pipe Material available in 3/4"-24" sizes, Check wide range of IBR Alloy Steel A335 P9 Boiler Pipe with EN 10204 3.1 certificate

Alloy Steel P9 Hollow Pipe Coating Types

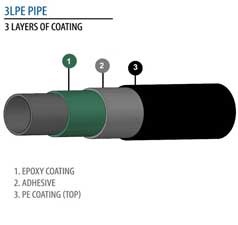

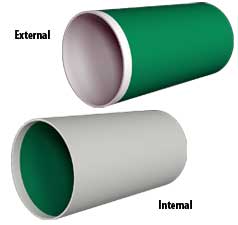

3LPE Coated

SA 335 Gr P5 3LPE Coated Pipes

Liquid Epoxy (LE)

ASTM A335 P5 LE Liquid Epoxy Coated Pipe

FBE Coated