Alloy Steel P11 Pipe

SA 335 Gr P11 Seamless Pipe and UNS K11597 High Pressure Pipe Supplier in India

Finding P11 Pipe suppliers who can supply in custom cut to length sizes? IBR approved ASME SA 335 P11 Boiler Pipe, ASTM A335 Gr P11 Alloy Steel Seamless Pipe and A335 P11 Tube manufacturer and exporter in India.

Difference Between ASTM A335 P11 Pipe and ASTM A335 P11 Tube

Pipes and tubes make up the main constituents of piping grade modules. Both these grades can be distinguished based on certain features.

- ASTM A335 P11 pipe is a module that is always round in shape. Tubes within this grade can be designed in square, rectangular, and round cross-sections.

- ASTM A335 P11 tube can be manufactured by both hot and cold rolling processes. Similarly, A335 P11 pipe can only be produced by the hot rolling process.

- Tubings in this grade can be shaped in correct dimensions easily, while P11 A335 pipes require special equipment to be precisely shaped.

- A335 P11 tube is stronger and more rigid than pipes of this grade.

Check updated ASTM A335 P11 Steel Chrome Pipe and SA335 P11 IBR Pipe Price per meter in India, check ASTM A335 gr P11 Material and P11 Seamless Pipe custom sizes in mm and lengths as per ANSI/ ASME B36.10M.

ASTM A335 P11 Pipe Vs ASME Sa 335 P11 Pipe

ASTM and ASME are two of the oldest standards that are used in manufacturing pipes in the A335 P11 grade. Both these modules have similar properties, but can be differentiated based on some features.

- ASTM A335 P11 pipe belongs to a standard that represents codes, dimensions, and standards for different technologies. ASME Sa 335 P11 pipe belongs to a grade that covers designs and manufacturing range for a range of pressure vessel equipment.

- ASME covers around 600 standards and codes for a range of technical materials. ASTM grade covers 12,000 or more standards for use in different products and services.

Is p11 seamless pipe suitable to use in boilers?

P11 seamless pipes possess superior strength and can withstand high pressures and temperatures, making them an ideal choice for manufacturing boiler grades. The grades allow boiler tubes to effectively process or condense fluids or gases effectively.

Is P11 Low Alloy Steel Pipe?

P11 alloy steel pipe is a low alloy grade. These versatile pipes possess lower content of chromium and molybdenum along with other elements embedded in the module.

We supplies ASTM A335 P11 Steel Chrome Pipe pipes to Oil & Gas Industry. PED 2014/68/EU and IBR certified SA335P11 Boiler Steel Pipe in India. Large Inventory of P11 pipe material supplier in Mumbai for High Temperature Range and Density.

Frequently used Alloy Steel P11 Pipe types

Looking for ASTM A335 grade P11 Alloy Pipe suppliers? Manufacturer and Distributor of Low Alloy ASTM A335 P11 Pipe Material and Alloy Steel SA 335 P11 High Pressure Pipe as per EN 10216-2/ GOST 550-75 standards

P11 Pipe Welding Procedure

Get Ferritic Alloy Steel ASTM A335P11 Seamless Pipe, NBR 5603 P11 Chrome Pipe and ASTM A335 P11 Alloy Steel Pipe in a variety of dimensions in ASME B36.19. Buy ISMT, Jindal, MSL, Bao steel ASTM A335 grade P11 Alloy Pipe in Mumbai

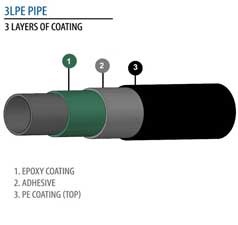

NBR 5603 P11 Chrome Pipe Coating Types

3LPE Coated

SA 335 Gr P5 3LPE Coated Pipes

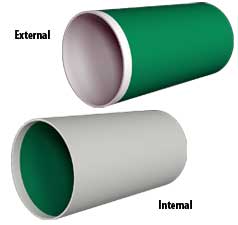

Liquid Epoxy (LE)

ASTM A335 P5 LE Liquid Epoxy Coated Pipe

FBE Coated

ASTM A335 P5 steel FBE Coated Pipe

Before

choosing A335 P11 Pipe Suppliers to check our deliveries of last five years.

Bangladesh, Jakarta -Indonesia, Dubai, Los Alamos -Mexico, Hong Kong, Turkey, Argentina, Germany, China, Oman, Saudi Arabia (KSA).

A335 P11 Pipe

Malaysia, Poland, Romania, Indonesia, Malaysia, Iran, Qatar, New Zealand, Brazil, Netherlands, United Arab Emirates (UAE).

A 335 P11 Chrome Pipe

USA, Chile, Ellington -United States, Canada, Sweden, United States, Greece, Singapore, Vietnam, Mexico, Denmark, Thailand, Finland.

ASTM A335 Gr P11 Pipe

Russia, Belgium, Norway, Egypt, Bahrain, Philippines, South Korea, Peru, Malaysia, Tehran -Iran, Colombia, Italy.

SA 335 Gr P11 Seamless Pipe

Spain, Jakarta, Europe, Australia, Jordan, Dammam -KSA, Japan, Istanbul -Turkey, NY 12203 (USA), Dubai -UAE, Kuala Lumpur.

Alloy P11 ASTM A335 Round Pipe

France, Singapore, Taiwan, South Africa, Portugal, Morocco, Czechia, Kuwait, Austria, United Kingdom (UK), Nigeria.