ASTM A403 WP316 Elbow and 316 Stainless Steel Tee Manufacturer in India

What is Stainless steel 316 pipe fittings?

Stainless steel 316 pipe fittings belong to an austenitic SS grade. These fittings are designed with a superior concentration of chromium, nickel, and molybdenum. The outstanding content embedded gives them enhanced corrosion and oxidation resistance across stress-induced systems. The 316 fittings also showcase good tolerance to pitting by acids in marine environments. The versatile grade of fittings perform well in high temperatures and are used to connect a range of piping equipment. The high-performance grade showcases excellent strength in different environmental conditions and influence their flow characteristics.

Can 316 stainless steel Buttweld Fitting be hardened?

A stainless steel 316 buttweld fitting can be hardened by heat treatment of the components. These versatile fittings are solution treated or annealed at temperatures of 1010 to 1120 degrees C. This is followed by rapid cooling or quench annealing.

ASME B16.9 316 Stainless Steel Reducing Tee vs ASTM A403 WP316 Equal Tee

A tee is a type of pipe fitting designed with three openings. The three outlet openings help in supplying fluids and gases across three channels. Tees are designed as reducing or equal tee and both can be classified on different characteristics.

- ASTM A403 WP316 Equal Tee is designed with three channels of equal sizes and dimensions. This enables them to facilitate an even flow of fluids and gases.

- ASME B16.9 316 Stainless Steel Reducing Tee is a type of fitting wherein one of the branch ports is smaller than the other two ports on the run.

Difference between UNS S31600 3D Elbow and Werkstoff No.1.4436 316 Stainless Steel 5D Elbow

Elbows are pipe fittings that are used to change the direction of the flow. Elbows are designed in bends, amongst which 5D and 3D are common and differentiated on certain key features.

- In the UNS S31600 3D elbow, the radius of the elbow is bent by 3 times its outer diameter. Werkstoff No.14436 316 stainless steel 5D elbow is a feature that is bent 5 times its outer diameter.

- The performance of a 5D elbow is smooth and allows for a swift direction change compared to a 3D elbow.

Table of Content

Stainless Steel 316 Pipe Fittings Specification

| Thickness | Schedule 20, 10, 30, 60,STD 40, XS, 100, 80, 120, 160, 140, XXS available with NACE MR 01-75 |

|---|---|

| Specifications | ASTM A403/ ASME SA403 |

| size | Seamless Butt Weld Fittings: Between 1/2 to 10 Inch Welded Butt Weld Fittings: Between 1/2 to 48 Inch |

| Dimensions | ANSI/ASME B16.9 and B16.28, BS10, BS4504, MSS-SP-43, BS4504, BS1560 |

| Type | DN15 upto DN1200 |

| Bending Radius | R=2D, 6D, 8D, 10D 3D, 5D, 1D, or Custom MSS Sp-43 Stainless Steel 316 Pipe Fitting |

| Size Range | From ½" NB upto 24" NB in Schedule160s, 40s, 80s, XXS, 10s,. (DN6~DN100) ASTM A403 SS 316 Buttweld Fitting |

| Elbows | Standard: ASME B16.9, ASME B16.28, DIN2605, ASME B16.25, MSS SP-75, JISB2311/ JISB2312/ JISB2313, BS, GB, ISO Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 4D, 2.5D, 3D, 7D to 40D, 5D, 6D . |

| Manufacturing process | Push, Forge, Cast, Press, etc. |

| Connection | Welding |

| Key markets and industries |

|

| Specialized manufacturer of | 90º Elbows, Pipe Bend, 45º Elbows, Tees, Crosses, Reducers, Pipe Cap, Stub End |

| Test Certificates | Raw Materials Certificate EN 10204/3.1B Third Party Inspection Report, etc 100% Radiography Test Report |

| uses and Application |

|

| We provide Material Test Certificates (MTC) as per EN 10204 3.2, and EN 10204 3.1 Test Certificates certifying NACE MR0103, NACE MR0175 | |

316 Stainless Steel Fittings Chemical Composition

| Grade | Mn | C | Si | S | P | Cr | Ni | Mo | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Stainless Steel 316 | 2.0 max | 0.08 max | 1.0 max | 0.030 max | 0.045 max | 16.00 - 18.00 | 11.00 - 14.00 | 2.00 - 3.00 | 67.845 min |

View chemical and mechanical composition of A403 Grade WP316 Stub End and SA403 WP316 Elbow, Buy UNS S31600 Concetric Reducer at low cost with MTR Certificate

SS 316 Fittings Mechanical Properties

| Melting Point | Density | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 1400 °C (2550 °F) | 8.0 g/cm3 | Psi - 75000 , MPa - 515 | Psi - 30000 , MPa - 205 | 35 % |

316 Pipe Fittings Equivalent

| STANDARD | JIS | WERKSTOFF NR. | UNS | BS | AFNOR | GOST | EN |

|---|---|---|---|---|---|---|---|

| Stainless Steel 316 | SUS 316 | 1.4401 / 1.4436 | S31600 | 316S31 / 316S33 | Z7CND17-11-02 | - | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

ASME B16.9 SS 316 Fittings Corrosion Resistance

- 1.4436 is slightly more resistant to corrosion than 1.4401, especially in chloride containing environments, due to the slightly higher molybdenum addition. This improved corrosion resistance is reflected by the slightly higher PRE values for 1.4436.

Stainless Steel 316 Pipe Fittings Standards

| Standard | Description |

|---|---|

| ANSI B16.9 | Factory-made wrought steel butt-welding fittings. |

| ASTM A182/ ASTM A182M | Forged or rolled alloy steel pipe flanges, forged fittings and valves and parts for high temperature service. Standard Specification for Wrought Austenitic Stainless Steel Piping fittings |

| ANSI B16.11 | Forged steel fittings socket-welding and threaded. Socket Welding and Threaded Forged fittings |

| ASTM A403/ ASTM A403M | Wrought austenitic stainless steel piping fittings. |

| ANSI B16.25 | Butt-welding ends. |

| ASTM A815/ ASTM A815M | Wrought ferritic, ferritic/austenitic and martensitic stainless steel piping fittings. |

| ISO 4144 | Stainless steel fittings threaded to ISO 7-1. |

| AS 2129 | Flanges for pipes, valves and fittings |

| MSS SP-95 | Swage(d) Nipples and Bull Plugs |

| ANSI/ASME B1.20.1 | Pipe threads, general purpose (inch). |

| BS3799 | Specification for Steel pipe fitting, screwed and Socket-welding for the petroleum industry |

| ANSI B16.5 | Steel pipe flanges and flanged fittings. |

| API 590-605 ASME B16.9 |

‘Factory-Made Wrought Buttwelding fittings |

| MSS SP43 | Wrought stainless steel butt-welding fitting. Wrought and Fabricated Butt-Welding fittings for Low Pressure, Corrosion Resistant Applications |

| ANSI – B 16.9 ASTM A403 – ASME SA403 |

‘Standard Specification for Wrought Austenitic Stainless Steel Piping fittings |

| BS21 | Threading. |

| ASME B16.25 | ‘Buttwelding Ends’ |

| ASME B16.28 | ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’ |

Exporter & supplier of ASTM A403 Grade WP316 Seamless Pipe Fittings as per MSS SP-43 standard and Check weight chart & dimensions of SS 316 End Cap.

316 Stainless Steel Tube Fittings Physical Properties

| Grade | Elastic Modulus (GPa) |

Density (kg/m3) |

Mean Co-eff of Thermal Expansion (µm/m/°C) | Elec Resistivity (nΩ.m) |

Thermal Conductivity (W/m.K) |

Specific Heat 0-100°C (J/kg.K) |

|||

|---|---|---|---|---|---|---|---|---|---|

| 0-100°C | 0-315°C | 0-538°C | At 100°C | At 500°C | |||||

| ASTM A403 WP316 Pipe Fittings | 193 | 8000 | 15.9 | 16.2 | 17.5 | 740 | 16.3 | 21.5 | 500 |

SS 316 Elbow Electrical Conductivity

| Electrical Resistivity (n.m) | 720 |

|---|

316 Stainless Pipe Fittings Tolerance

| Nominal Diameter | I.D.For End | O.D.For Bevel End | Wall Thickness | Elbow | Tee | Reducer | Cap | 180°Elbow | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | A | B | M | C | H | E | O | Roughness | K | |||

| 15-65 | 1/2-2 1/2 | 0.8 | +1.6/-0.8 | -12.50% | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 3.2 | 6.4 | 0.8 | 6.4 |

| 80-100 | 3-4 | 1.6 | 1.6 | 6.4 | |||||||||

| 125-200 | 5-8 | +2.4/-1.6 | |||||||||||

| 250-450 | 10-18 | 3.2 | +4/-3.2 | 2.4 | 2.4 | 2.4 | 2.4 | 2.4 | 9.6 | ||||

| 500-600 | 20-24 | 4.8 | +6.4/-4.8 | 3.2 | 3.2 | 3.2 | 3.2 | 4.8 | 9.6 | ||||

| 650-750 | 26-30 | ||||||||||||

| 4.8 | 4.8 | 4.8 | 4.8 | ||||||||||

| 800-1200 | 32-48 | ||||||||||||

| 1250-1500 | 50-60 | 6.4 | +9.6/-6.4 | 9.6 | 9.6 | 9.6 | 9.6 | 9.6 | |||||

| 1550-1750 | 62-70 | 9.6 | +12.7/-9.6 | 12.7 | 12.7 | ||||||||

| 1800-2000 | 72-80 | 12 | +16/-12 | 16 | 16 | ||||||||

ASTM A403 WP316 Fittings WP Grade Chart

| WP316-WX | RT all welds with or without filler metal. |

|---|---|

| CR | Corrosion resistant grade. S through WU Classes do not apply. |

| WP316-WU | UT all welds with or without filler metal. |

| WP316-S | Seamless |

| WPgrade-grade-class | Insert grades (316) and class (S,W,WX, or WU). Applies to fittings meeting all chemical and physical requirements of both grades. |

| WP316-W | Welded, RT or UT all pipe starting material welds made with filler metal. All fitting manufacturer welds except as excluded in A/SA403 paragraph 5.4.3. If UT is substituted for RT, all welds must be examined 100% for their length as required by A/SA403 paragraph 5.6 |

316 SS Pipe Fittings Testing

- Hardness test

- Flaring test

- Flattening test

- Positive material identification test

- Mechanical test

- Intergranular corrosion test

- Macro test

- Chemical test

- Pitting resistance test

Types of Stainless Steel 316 Pipe Fittings

316 Stainless Steel Welded Pipe Fittings Hardness

| Brinell hardness (HB): (+AT) | 200 |

|---|---|

| Brinell hardness (HB): (+A) | 215 |

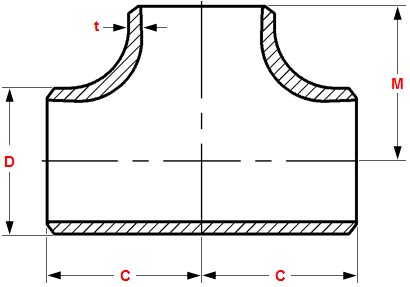

A403 Gr Wp316 Tee Dimension

| NPS | Center to End M | Outside Dia D | Center to End C |

|---|---|---|---|

| 1/2 | 25 | 21.3 | 25 |

| 3/4 | 29 | 26.7 | 29 |

| 1 | 38 | 33.4 | 38 |

| 1.1/4 | 48 | 42.2 | 48 |

| 1.1/2 | 57 | 48.3 | 57 |

| 2 | 64 | 60.3 | 64 |

| 2.1/2 | 76 | 73 | 76 |

| 3 | 86 | 88.9 | 86 |

| 3.1/2 | 95 | 101.6 | 95 |

| 4 | 114.3 | 105 | 105 |

| 5 | 141.3 | 124 | 124 |

| 6 | 168.3 | 143 | 143 |

| 8 | 219.1 | 178 | 178 |

| 10 | 273 | 216 | 216 |

| 12 | 323.8 | 254 | 254 |

| 14 | 355.6 | 279 | 279 |

| 16 | 406.4 | 305 | 305 |

| 18 | 457 | 343 | 343 |

| 20 | 508 | 381 | 381 |

| 22 | 559 | 419 | 419 |

| 24 | 610 | 432 | 432 |

| 26 | 495 | 660 | 495 |

| 28 | 521 | 711 | 521 |

| 30 | 559 | 762 | 559 |

| 32 | 597 | 813 | 597 |

| 34 | 635 | 864 | 635 |

| 36 | 673 | 914 | 673 |

| 38 | 711 | 965 | 711 |

| 40 | 749 | 1016 | 749 |

| 42 | 762 | 1067 | 711 |

| 44 | 813 | 1118 | 762 |

| 46 | 851 | 1168 | 800 |

| 48 | 889 | 1219 | 838 |

Stainless Steel 316 Pipe Fittings Density

| Density (kilogram/m3) | 8000 |

|---|

Schedule 40 316 Stainless Steel Pipe Fittings Thermal Conductivity

| Thermal Conductivity(W/m.K) | |

|---|---|

| at 5000C | at 1000C |

| 21.5 | 16.2 |

Dimensional Tolerances Straight Tee ASME B16.9

| Nominal Pipe Sizes | 10 to 18 | 3 to 3.1/2 | 5 to 8 | 1/2 to 2.1/2 | 32 to 48 | 4 | 20 to 24 | 26 to 30 |

|---|---|---|---|---|---|---|---|---|

| Inside Dia at End | 3.2 | 1.6 | 1.6 | 0.8 | +6.4 -4.8 | 1.6 | 4.8 | +6.4 -4.8 |

| Out Dia at Bevel (D) | +4 -3.2 | 1.6 | +2.4 -1.6 | +1.6 -0.8 | +6.4 -4.8 | 1.6 | +6.4 -4.8 | +6.4 -4.8 |

| Center to End (C / M) | 2 | 2 | 2 | 2 | 5 | 2 | 2 | 3 |

| Wall Thk (t) | Not less than 87.5% of Nominal Wall Thickness | |||||||

Stainless Steel 316 Pipe Fittings Angularity Tolerance

| Nominal Size | DN | 450-600 | 15-100 | 650-750 | 125-200 | 800-1050 | 250-300 | 1300-1500 | 350-400 | 1100-1200 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS | 18-24 | 1/2 - 4 | 26-30 | 5-8 | 32-42 | 10-12 | 52-60 | 14-16 | 44-48 | ||

| Angularity Tolerance |

Off Plain | P | 10 | 2 | 10 | 4 | 13 | 5 | 20 | 6 | 19 |

| Off Angle | Q | 4 | 1 | 5 | 2 | 5 | 3 | 6.4 | 3 | 5 | |

SS 316 Reducer Dimension Chart

| Dimensional Tolerances of Eccentric and Concentric Reducers ASME B16.9 | ||||

|---|---|---|---|---|

| Nominal Pipe Sizes | 5 to 8 | 3 to 3.1/2 | 4 | 1/2 to 2.1/2 |

| I.D at End | 1.6 | 1.6 | 1.6 | 0.8 |

| O.D at Bevel (D) | + 2.4 - 1.6 | 1.6 | 1.6 | + 1.6 - 0.8 |

| Overall Length (H) | 2 | 2 | 2 | 2 |

| Nominal Pipe Sizes | 32 to 48 | 20 to 24 | 26 to 30 | 10 to 18 |

| I.D at End | + 6.4 - 4.8 | 4.8 | + 6.4 - 4.8 | 3.2 |

| O.D at Bevel (D) | + 6.4 - 4.8 | + 6.4 - 4.8 | + 6.4 - 4.8 | + 4 - 3.2 |

| Overall Length (H) | 5 | 2 | 5 | 2 |

| Wall Thickness (t) | Not less than 87.5% of Nominal Wall Thk. | |||

| Dimensional tolerances are in mm unless otherwise indicated and are equal ± except as noted. | ||||

316 SS Fittings Thermal Expansion Cofficient

| Mean Coefficient of Thermal Expansion (m/m/0C) | ||

|---|---|---|

| 0-3150C | 0-1000C | 0-5380C |

| 17.8 | 17.2 | 18.4 |

Check Price List of ANSI/ASME B16.9 SS 316 Buttweld Fittings, ASTM A403 WP316 Tee are used in sea water/ chemical pipelines, Contact us today to buy Din 1.4401 Stub End and Reducing Tee, Refer A403 Grade Wp316 Long Radius and Short Radius Elbow Weight Chart

AISI 316 Butt Weld Elbows Dimensional Tolerances

| Nominal Pipe Sizes | 5 to 8 | 3 to 3.1/2 | 4 | 1/2 to 2.1/2 |

|---|---|---|---|---|

| Inside Dia at End | 1.6 | 1.6 | 1.6 | 0.8 |

| Outside Dia at Bevel (D) |

+ 2.4 - 1.6 |

1.6 | 1.6 | + 1.6 - 0.8 |

| Center to End LR (A/B) | 2 | 2 | 2 | 2 |

| Nominal Pipe Size | 32 to 48 | 20 to 24 | 26 to 30 | 10 to 18 |

| Center to End 3D (A/B) | 3 | 3 | 3 | 3 |

| Outside Dia at Bevel (D) |

+ 6.4 - 4.8 |

+ 6.4 - 4.8 |

+ 6.4 - 4.8 |

+ 4 - 3.2 |

| Center to End LR (A/B) | 5 | 2 | 3 | 2 |

| Inside Dia at End | + 6.4 - 4.8 |

4.8 | + 6.4 - 4.8 |

3.2 |

| Center to End 3D (A/B) | 6 | 3 | 6 | 3 |

| Wall Thickness (t) | Not less than 87.5% of Nominal Wall Thickness | |||

Stainless Steel 316 Pipe Fittings Weight Chart

| NPS (Normal Size Of Steel Pipe) | Schedule 40S | Schedule 10S | Schedule 80S | ||||||

|---|---|---|---|---|---|---|---|---|---|

| ASME B16.9 Butt weld 45 Deg Elbows | ASME B16.9 Butt weld 90 Deg Elbows | ASME B16.9 Butt weld Equal Tee | ASME B16.9 Butt weld 45 Deg Elbow | ASME B16.9 Butt weld 90 Deg Elbow | ASME B16.9 Butt weld Equal Tee | ASME B16.9 Butt weld 45 Deg Elbow | ASME B16.9 Butt weld 90 Deg Elbow | ASME B16.9 Butt weld Equal Tee | |

| 8 | 0.02 | 0.03 | 0.06 | 0.01 | 0.02 | 0.03 | 0.03 | 0.04 | 0.07 |

| 10 | 0.02 | 0.03 | 0.03 | 0.02 | 0.03 | 0.05 | 0.04 | 0.06 | 0.09 |

| 15 | 0.04 | 0.08 | 0.10 | 0.03 | 0.06 | 0.09 | 0.05 | 0.10 | 0.14 |

| 20 | 0.04 | 0.08 | 0.17 | 0.03 | 0.07 | 0.13 | 0.05 | 0.11 | 0.20 |

| 25 | 0.11 | 0.15 | 0.29 | 0.08 | 0.14 | 0.28 | 0.14 | 0.22 | 0.38 |

| 32 | 0.17 | 0.26 | 0.59 | 0.11 | 0.23 | 0.49 | 0.23 | 0.40 | 0.68 |

| 40 | 0.23 | 0.40 | 0.86 | 0.17 | 0.30 | 0.68 | 0.29 | 0.51 | 1.02 |

| 50 | 0.4 | 0.70 | 1.28 | 0.25 | 0.50 | 0.85 | 0.59 | 0.91 | 1.59 |

| 65 | 0.77 | 1.40 | 2.19 | 0.48 | 0.85 | 1.41 | 0.99 | 1.81 | 3.13 |

| 80 | 1.08 | 2.20 | 3.31 | 0.63 | 1.25 | 1.77 | 1.50 | 2.97 | 4.45 |

| 90 | 1.42 | 2.83 | 4.08 | 0.75 | 1.70 | 2.67 | 2.00 | 4.00 | 5.44 |

| 100 | 2.09 | 4.47 | 5.27 | 1.08 | 2.10 | 3.46 | 2.81 | 6.18 | 7.71 |

| 150 | 5.44 | 10.89 | 10.99 | 2.72 | 5.45 | 8.07 | 8.16 | 16.32 | 13.61 |

| 200 | 10.77 | 21.54 | 20.91 | 5.33 | 10.20 | 15.65 | 16.56 | 33.11 | 28.12 |

| 250 | 19.27 | 38.56 | 35.38 | 9.75 | 18.15 | 26.46 | 25.86 | 51.71 | 49.90 |

| 300 | 29.71 | 59.42 | 62.14 | 13.62 | 25.80 | 39.46 | 39.69 | 79.38 | 83.91 |

ASTM A403 WP316 Buttweld Pipe Fittings Melting Point

| Property | Value |

|---|---|

| Melting point | 1230 - 1480 °C |

SUS 316 Elbows Dimensions

| NPS | 45° 3D Center to End B | 45° Long Radius Center to End B | 90° Long Radius Center to End A | 90° 3D Center to End A | Outer Dia D |

|---|---|---|---|---|---|

| 3.1/2 | 111 | 57 | 133 | 267 | 101.6 |

| 4 | 127 | 64 | 152 | 305 | 114.3 |

| 5 | 157 | 79 | 190 | 381 | 141.3 |

| 6 | 189 | 95 | 229 | 457 | 168.3 |

| 8 | 252 | 127 | 305 | 610 | 219.1 |

| 1/2 | 16 | 38 | 21.3 | ||

| 3/4 | 24 | 19 | 38 | 57 | 26.7 |

| 1 | 31 | 22 | 38 | 76 | 33.4 |

| 1.1/4 | 39 | 25 | 48 | 95 | 42.2 |

| 1.1/2 | 47 | 29 | 57 | 114 | 48.3 |

| 2 | 63 | 35 | 76 | 152 | 60.3 |

| 2.1/2 | 79 | 44 | 95 | 190 | 73 |

| 3 | 95 | 51 | 114 | 229 | 88.9 |

| 10 | 316 | 159 | 381 | 762 | 273 |

| 12 | 378 | 190 | 457 | 914 | 323.8 |

| 14 | 441 | 222 | 533 | 1067 | 355.6 |

| 16 | 505 | 254 | 610 | 1219 | 406.4 |

Stainless Steel 316 Pipe Fittings HS Code

| Name Of Hs Code | Despriction List | Shipments |

|---|---|---|

| 73072200 | ANSI/ ASME B16.11 Threaded (NPT) Pipe Elbow And Bend | 482 |

| 7307 | Pipe Tube Or ANSI/ ASME B16.9 Pipe Fittings (For Socket Weld Couplings And Buttweld Pipe Elbow) | |

| 73072300 | Buttweld/ Welded/ Seamless Fitting | 384 |

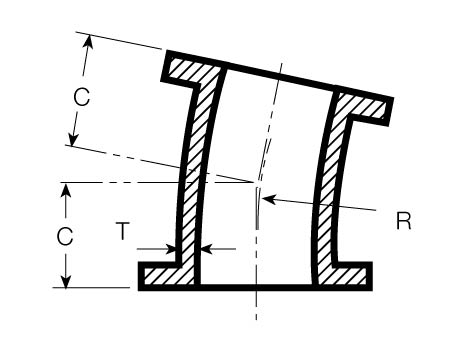

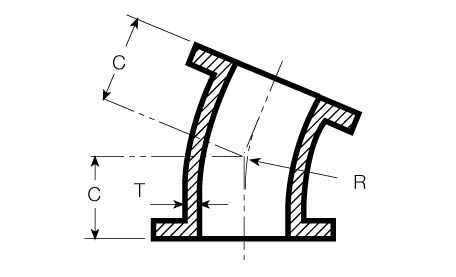

S31603 Pipe Bend Dimensions

11 1/4° BENDS

| Size (in.) |

C (in.) |

Pressure Rating (psi) |

T (in.) |

Weight (lbs.) |

R (in.) |

|---|---|---|---|---|---|

| 4 | 4 | 250 | 0.52 | 35 | 20.31 |

| 6 | 5 | 250 | 0.55 | 55 | 30.5 |

| 8 | 5.5 | 250 | 0.6 | 90 | 35.5 |

| 10 | 6.5 | 250 | 0.68 | 135 | 45.69 |

| 12 | 7.5 | 250 | 0.75 | 200 | 55.81 |

| 14 | 7.5 | 250 | 0.66 | 225 | 50.75 |

| 16 | 8 | 250 | 0.7 | 285 | 55.81 |

| 18 | 8.5 | 250 | 0.75 | 335 | 60.94 |

| 20 | 9.5 | 250 | 0.8 | 435 | 71.06 |

| 24 | 11 | 250 | 0.89 | 645 | 76.12 |

| 30 | 15 | 250 | 1.03 | 1145 | 116.75 |

| 36 | 18 | 250 | 1.15 | 1800 | 147.25 |

| 42 | 21 | 250 | 1.28 | 2680 | 177.69 |

| 48 | 24 | 250 | 1.42 | 3690 | 208.12 |

| 54 | 12 | 2506 | 0.9 | 2100 | 38.07 |

| 60 | 10.5 | 2506 | 0.94 | 2665 | 40.61 |

| 64 | 9.5 | 2506 | 0.99 | 3585 | 38.07 |

22 1/2° BENDS

| Size (in.) |

C (in.) |

Pressure Rating (psi) |

T (in.) |

Weight (lbs.) |

R (in.) |

|---|---|---|---|---|---|

| 4 | 4 | 250 | 0.52 | 35 | 10.06 |

| 6 | 5 | 250 | 0.55 | 55 | 15.06 |

| 8 | 5.5 | 250 | 0.6 | 90 | 17.62 |

| 10 | 6.5 | 250 | 0.68 | 130 | 22.62 |

| 12 | 7.5 | 250 | 0.75 | 200 | 27.62 |

| 14 | 7.5 | 250 | 0.66 | 225 | 25.12 |

| 16 | 8 | 250 | 0.7 | 285 | 27.62 |

| 18 | 8.5 | 250 | 0.75 | 335 | 30.19 |

| 20 | 9.5 | 250 | 0.8 | 435 | 35.19 |

| 24 | 11 | 250 | 0.89 | 640 | 37.69 |

| 30 | 15 | 250 | 1.03 | 1140 | 57.81 |

| 36 | 18 | 250 | 1.15 | 1790 | 72.88 |

| 42 | 21 | 250 | 1.28 | 2665 | 88 |

| 48 | 24 | 250 | 1.42 | 3665 | 103.06 |

| 54 | 14 | 250 | 0.9 | 2260 | 37.65 |

| 60 | 14 | 250 | 0.94 | 2985 | 38.36 |

| 64 | 13.5 | 250 | 0.99 | 3995 | 39.06 |

316 Stainless Steel Pipe Fittings Elastic Modulus

| Elastic Modulus (GPa) | 193 |

|---|

UNS S31600 ASTM A403 WP316 Buttweld Pipe Fittings Heat Treatment

| Heat Treatment Range |

| At the temperature between 925 to 950 Deg. C. |

316 Stainless Fittings Marking

- Name of Manufacturer = (SPMetal)

- Size = (10")

- Fittings Type = (End Cap)

- Schedule = (SCH 80)

- Material Designation = (ASTM A403 WP316)

- Standard = (ASME B16.9)

- Heat No. = (160087)

- Country Name = (Made In India)

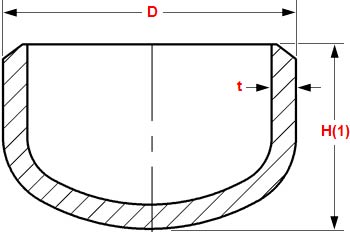

Dimensional Tolerances of End Caps

| Nominal Pipe Size | 3 to 3.1/2 | 1/2 to 2.1/2 | 5 to 8 | 4 |

|---|---|---|---|---|

| Outside Diameter at Bevel (D) |

1.6 | + 1.6 - 0.8 |

+ 2.4 - 1.6 |

1.6 |

| Inside Diameter at End | 1.6 | 0.8 | 1.6 | 1.6 |

| Overall Length (H) | 3 | 3 | 6 | 3 |

| Nominal Pipe Size | 20 to 24 | 10 to 18 | 32 to 48 | 26 to 30 |

| Outside Diameter at Bevel (D) |

+ 6.4 - 4.8 |

+ 4 - 3.2 |

+ 6.4 - 4.8 |

+ 6.4 - 4.8 |

| Inside Diameter at End | 4.8 | 3.2 | + 6.4 - 4.8 |

+ 6.4 - 4.8 |

| Overall Length (H) | 6 | 6 | 10 | 10 |

| Wall Thickness (t) | Not less than 87.5% of Nominal Wall Thickness | |||

Werkstoff No.1.4436 316 Stainless Steel Fittings Size Chart

| Grade 316 Stainless Steel Butt Weld Fittings | |

|---|---|

| Sizes | 1/2" – 12" |

| Stainless Steel WP316 Fittings Types | Stainless Steel ASTM A403 WP316 90º LRs, 90º SRs, 45º Elbows, Stainless Steel UNS S30403 Concentric Reducers, ASTM A403 WP316 Eccentric Reducers, ASME SA403 Stainless Steel 316 Tees, Reducing Tees and Stub Ends Fittings |

| Schedules | Sch 10S - 80S |

- Size: 1/8'' to 104'', SCH5S~SCH160

- Connection End: Butt-welded.

| Product | Size* | Wall Thickness** | Seamless | Welded |

|---|---|---|---|---|

| Reducer | 1/2"-24" | Schedule 10S~XXS | √ | √ |

| 8"-104" | Schedule 5S~80S/XS | √ | ||

| Tee | 1/2"-24" | Schedule 10S~XXS | √ | √ |

| 8"-104" | Schedule 5S~80S/XS | √ | ||

| Lap Joint Stub End | 1/2"-24" | Schedule 5S~80S/XS | √ | √ |

| 8"-80" | Schedule 5S~80S/XS | √ | ||

| Elbow | 1/2"-24" | Schedule 10S~XXS | √ | √ |

| 8"-104" | Schedule 5S~80S/XS | √ | ||

| Cap | 1/2"-80" | Schedule 10S~SCH160 | √ |

Alloy 316 End Cap Dimensions

| NPS | LENGTH H |

O.D. D |

LENGTH H1 |

|---|---|---|---|

| 1/2 | 25 | 21.3 | 25 |

| 3/4 | 25 | 26.7 | 25 |

| 1 | 38 | 33.4 | 38 |

| 1.1/4 | 38 | 42.2 | 38 |

| 1.1/2 | 38 | 48.3 | 38 |

| 2 | 38 | 60.3 | 44 |

| 2.1/2 | 38 | 73 | 51 |

| 3 | 51 | 88.9 | 64 |

| 3.1/2 | 64 | 101.6 | 76 |

| 4 | 64 | 114.3 | 76 |

| 5 | 76 | 141.3 | 89 |

| 6 | 89 | 168.3 | 102 |

| 8 | 102 | 219.1 | 127 |

| 10 | 127 | 273 | 152 |

| 12 | 152 | 323.8 | 178 |

| 14 | 165 | 355.6 | 191 |

| 16 | 178 | 406.4 | 203 |

| NPS | LENGTH H |

O.D. D |

LENGTH H1 |

|---|---|---|---|

| 18 | 203 | 457 | 229 |

| 20 | 229 | 508 | 254 |

| 22 | 254 | 559 | 254 |

| 24 | 267 | 610 | 305 |

| 26 | 267 | 660 | |

| 28 | 267 | 711 | |

| 30 | 267 | 762 | |

| 32 | 267 | 813 | |

| 34 | 237 | 864 | |

| 36 | 267 | 914 | |

| 38 | 305 | 965 | |

| 40 | 305 | 1016 | |

| 42 | 305 | 1067 | |

| 44 | 343 | 1118 | |

| 46 | 343 | 1168 | |

| 48 | 343 | 1219 |

How to make an 316 SS Reducing Tee Pattern?

- Stainless Equal Tee Formula

- 90 Degree Elbow

- 4" X 4" Inches

- Pipe Outside Daimeter (O.D.) X 2/5

- For Example

- 4 Inches Pipe (O.D.) Outside Daimeter = 114.30

- 114.30 X 2 = 228.60 / 5 = 45.72 (MM/ Millimeter) cut back

We provide multiple payment options to buy A403 Wp316 Material, SS 316 Equal / Reducing Tee, 3D / 5D Bend Supplier in Mumbai, Buy directly from 316 Stainless Steel Fittings manufacturer in India

SS 316 Pipe Fittings Price List

| Products | Fitting Pipe Size | 316 Stainless Steel |

|---|---|---|

| STAINLESS STEEL PIPE FITTING SS 316 TC LINER L=15mm T:1.65mm SIZE 1.0(2500 PCS) | 1/8 in x 1/8 in | $6.60 |

| PIPE FITTING STAINLESS STEEL SA403 WP316-WX,90D ELBOW(L),S80S, 200DN (15 PCS) | 1/4 in x 1/4 in | $7.60 |

| PIPE FITTING STAINLESS STEEL SA 403 GR. WP316, DN100,SCH 10S,90 DEGREE ELBOW(SR),ASME,BW,SMLS,DIM. AS PER ASME(1 PCS) | 3/8 in x 3/8 in | $9.80 |

| STAINLESS STEEL PIPE FITTING SS 316 TC LINER L=15mm T:1.65mm SIZE 1.0(2500 PCS) | 1/2 in x 1/2 in | $18.67 |

| PIPE FITTING STAINLESS STEEL SA 403 GR WP316 DN65,SCH 10S,45 DEGREE ELBOW(LR),ASME,BW,SMLS,DIM,AS PER ASME/ANSI | 3/4 in x 3/4 in | $25.33 |

| PIPE FITTING STAINLESS STEEL GR WP316 DN50,SCH 80,EQUAL TEE ,BW,SMLS B16.9 | 1 in x 1 in | $36.51 |

Stainless Steel 316 Pipe Fittings Inventory

| Stainless Steel 316 Pipe Fittings | 316 Stainless Steel 10D Elbow |

| 316 Stainless Steel Fittings | Ss 316 Union |

| Ss 316 Fittings | 316 Ss Reducing Tee |

| 316 Pipe Fittings | SS 316 Equal Tee |

| Ss316 Elbow | AISI 316 Lateral Tee |

| 316 Stainless Fittings | SUS 316 Straight Tee |

| Ss 316 Pipe Fittings | UNS S31603 Barred Tee |

| 316 Stainless Steel Tube Fittings | SS 316 Concentric Reducer |

| Ss 316 Elbow | WNR 1.4401 Eccentric Reducer |

| 316 Stainless Pipe Fittings | 316 SS Stub Ends |

| 316 Stainless Steel Elbows | Stainless Steel 316 Buttweld Fittings |

| 316 Ss Pipe Fittings | 316 Stainless Steel Elbow |

| Ss 316 Nipple | 316 Stainless Steel Weld Fittings |

| 316 Stainless Steel Welded Pipe Fittings | ASTM A403 WP316 Buttweld Pipe Fittings |

| Schedule 40 316 Stainless Steel Pipe Fittings | 316 Stainless Steel Reducer |

| 316 Stainless Steel 90 Degree Elbow | Reducer SS 316 |

| 316 SS Fittings | 316 stainless steel pipe fittings |

| SCH 40 SS 316 Elbow | UNS S31600 ASTM A403 WP316 Buttweld Pipe Fittings |

| ASTM A403 WP316 45 Deg Elbow | ASME B16.9 SS 316 Fittings |

| SCH 10 SA403 WP316 2D Elbow | Werkstoff No.1.4436 316 Stainless Steel Fittings |

| SCH 20 SA 403 Wp 316 3D Elbow | ASTM A403 WP316 Fittings |

| Gr Wp316 5D Elbow | ANSI B16.9 316 Stainless Steel Elbow |

SS 316 Pipe Fittings Documentation

- Fumigation Certificates

- Guarantee Letter

- Raw Material Test Reports

- Fumigation Certificates

- Heat Treatment Charts

- Commercial Invoice which includes HS Code

- QAP (Quality Assurance Plan)

- NABL approved Laboratory Test Reports

Searching for

Stainless Steel 316 Pipe Fittings supplier in your country? Checklist of material we export in the following areas.

UNS S31600 ASTM A403 WP316 Buttweld Pipe Fittings

Bangladesh, Jakarta -Indonesia, Dubai, Los Alamos -Mexico, Hong Kong, Turkey, Argentina, Germany, China, Oman, Saudi Arabia (KSA).

ASME B16.9 SS 316 Fittings

Malaysia, Poland, Romania, Indonesia, Malaysia, Iran, Qatar, New Zealand, Brazil, Netherlands, United Arab Emirates (UAE).

Werkstoff No.1.4436 316 Stainless Steel Fittings

USA, Chile, Ellington -United States, Canada, Sweden, United States, Greece, Singapore, Vietnam, Mexico, Denmark, Thailand, Finland.

ASTM A403 WP316 Fittings

Russia, Belgium, Norway, Egypt, Bahrain, Philippines, South Korea, Peru, Malaysia, Tehran -Iran, Colombia, Italy.

ANSI B16.9 316 Stainless Steel Elbow

Spain, Jakarta, Europe, Australia, Jordan, Dammam -KSA, Japan, Istanbul -Turkey, NY 12203 (USA), Dubai -UAE, Kuala Lumpur.

316 Stainless Steel Tee

France, Singapore, Taiwan, South Africa, Portugal, Morocco, Czechia, Kuwait, Austria, United Kingdom (UK), Nigeria.