ASTM A403 WP304L Elbow and SS 304L Buttweld Fittings Manufacturer in India

What Is Stainless Steel 304l Pipe Fittings?

Stainless steel 304l pipes fittings are a low carbon austenitic grade. The range of fittings is designed possessing a superior chemical content of nickel and chromium. The outstanding content gives these modules enhanced corrosion and oxidation resistance across stress-induced environments. The robust 304l fittings can function well in ambient to high-temperature and pressure systems. These high-strength components play a pivotal role in influencing the characteristics of the flow in the piping system.

Mss Sp-43 Stainless Steel 304l Long Stubend Vs Mss Sp-79 UNS S30403 Short Stubend

Stub ends are mechanical joints that are manufactured by making use of two individual modules. The stub ends can be categorized as long or short stubs and both these components can be distinguished on certain features.

- An Mss Sp-43 Stainless Steel 304l Long Stub end is a type of fitting that is designed with a flared end on the exterior while possessing a long length of the pipe on the outside.

- The Mss Sp-79 UNS S30403 Short Stub end is a fitting type that is flared on the exterior while possessing a short length of the pipe on the outside.

How Do You Anneal 304l Stainless Steel Buttweld Fitting?

Buttweld fitting is a versatile high-strength type of fittings. The fittings can be annealed by heating the grade at temperatures above 1900 degrees, followed by rapid air quenching. Annealing at these temperatures allows the fittings to achieve the best resistances while preventing excess oxidation on the surface of the fitting.

Difference Between Sus 304l Stainless Steel Equal Cross Vs ASTM A403 Wp304l Reducing Cross

A cross fitting is an element that has 4 outlets allowing it to connect four lines using a single port. The fittings are designed in equal and reducing cross, and both have distinct functions that help in classifying them in the system.

- A 304l stainless steel equal cross is a type of fitting that is designed with outlets having equal diameters. They allow for an even distribution of flow in the system.

- In a ASTM A403 Wp304l reducing cross, one or more of the ports are reduced in size. This ensures that there is reduction of the flow in one of the lines.

Table of Content

SS 304L Fittings Material Specification

| Thickness | Schedule 20, 10, 30, 60,STD 40, XS, 100, 80, 120, 160, 140, XXS available with NACE MR 01-75 |

|---|---|

| Specifications | ASTM A403/ ASME SA403 |

| size | Seamless Butt Weld Fittings: Between 1/2 to 10 Inch Welded Butt Weld Fittings: Between 1/2 to 48 Inch |

| Dimensions | ANSI/ASME B16.9 and B16.28, BS10, BS4504, MSS-SP-43, BS4504, BS1560 |

| Type | DN15 upto DN1200 |

| Bending Radius | R=2D, 6D, 8D, 10D 3D, 5D, 1D, or Custom MSS Sp-43 Stainless Steel 304L Pipe Fitting |

| Size Range | From ½" NB upto 24" NB in Schedule 160s, 40s, 80s, XXS, 10s,. (DN6~DN100) ASTM A403 SS 304L Buttweld Fitting |

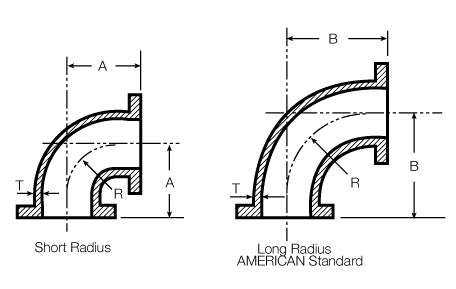

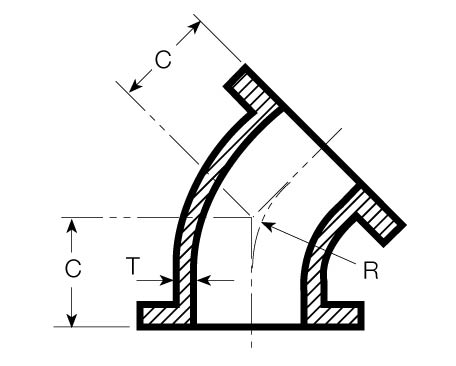

| Elbows | Standard: ASME B16.9, ASME B16.28, DIN2605, ASME B16.25, MSS SP-75, JISB2311/ JISB2312/ JISB2313, BS, GB, ISO Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 4D, 2.5D, 3D, 7D to 40D, 5D, 6D . |

| Manufacturing process | Push, Forge, Cast, Press, etc. |

| Connection | Welding |

| Key markets and industries |

|

| Specialized manufacturer of | 90º Elbows, Pipe Bend, 45º Elbows, Tees, Crosses, Reducers, Pipe Cap, Stub End |

| Test Certificates | Raw Materials Certificate EN 10204/3.1B Third Party Inspection Report, etc 100% Radiography Test Report |

| uses and Application |

|

| We provide Material Test Certificates (MTC) as per EN 10204 3.2, and EN 10204 3.1 Test Certificates certifying NACE MR0103, NACE MR0175 | |

ASTM A403 WP304L Elbow Chemical Composition

| Grade | S | Mn | P | C | Cr | Si | Mo | Ni | N |

|---|---|---|---|---|---|---|---|---|---|

| SS 304L | 0.03 max | 2.0 max | 0.045 max | 0.035 max | 18 - 20 | 1.0 max | - | 8 - 13 | - |

Manufacturer of Schedule 10/10S/40/40S/120/160 BW ASTM A403 WP304L Pipe Bend/ Return Bends and SA 403 WP 304L Long and Short Radius Elbow supplier with with Hydrostatic (Hydro) Testing as per ASME B16.9.

304L Stainless Steel Elbow Mechanical Properties

| Density | Tensile Properties | Melting Point | Elongation | Yield Properties (0.2%Offset) |

|---|---|---|---|---|

| 8.0 g/cm3 | Psi - 75000 , MPa - 515 | 1400 °C (2550 °F) | 40 % | Psi - 30000 , MPa - 205 |

Stainless Steel 304L Pipe Fittings Equivalent

| STANDARD | JIS | UNS | GOST | WERKSTOFF NR. | BS | EN | AFNOR |

|---|---|---|---|---|---|---|---|

| SS 304L | SUS 304L | S30403 | 03Х18Н11 | 1.4306 / 1.4307 | 3304S11 | X2CrNi18-9 / X2CrNi19-11 | Z3CN18-10 |

SS 304L Butt weld Fittings Melting Point

| Property | Value |

|---|---|

| Melting Point | 1450 °C |

ANSI B16.9 SS WP304L End Pipe Cap Standard

| Mss SP75 | Long Radius Elbows, 3R elbows, straight tees, reducing outlet tees, caps, reducers | |

|---|---|---|

| ASME B16.28 | Short Radius Elbows, Short Radius 180-deg Returns | |

| MSS SP43 | Long Radius Elbows, Reducing and Straight-on-the-Outlet Tees, caps, Lap Joint Stub ends, long radius 180 Deg returns, concentric/ eccentric reducers | Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications |

| ASME B16.9 ASTM A403 WP304 Fittings | Long Radius Reducing Elbows, Long Radius Elbows, Short Radius Elbows, Long Radius Returns, Short Radius 180-deg Rerurns, Straight Tees, 3D elbows, Straight Crosses, Reducing Outlet Crosses, Reducing Outlet Tees, Lap Joint Stub Ends, Reducers,Caps | Factory-Made Wrought Buttwelding Fittings |

ASME B16.9 SS 304L Seamless Pipe Fittings Physical Properties

| Grade | Density (kg/m3) | Specific Heat 0-1000C (J/kg.K) | Mean Coefficient of Thermal Expansion (m/m/0C) | Elastic Modulus (GPa) | Thermal Conductivity (W/m.K) | Electrical Resistivity (n.m) | |||

|---|---|---|---|---|---|---|---|---|---|

| 0-3150C | 0-1000C | 0-5380C | at 1000C | at 5000C | |||||

| Stainless Steel 304L | 8000 | 500 | 17.8 | 17.2 | 18.4 | 193 | 16.2 | 21.5 | 720 |

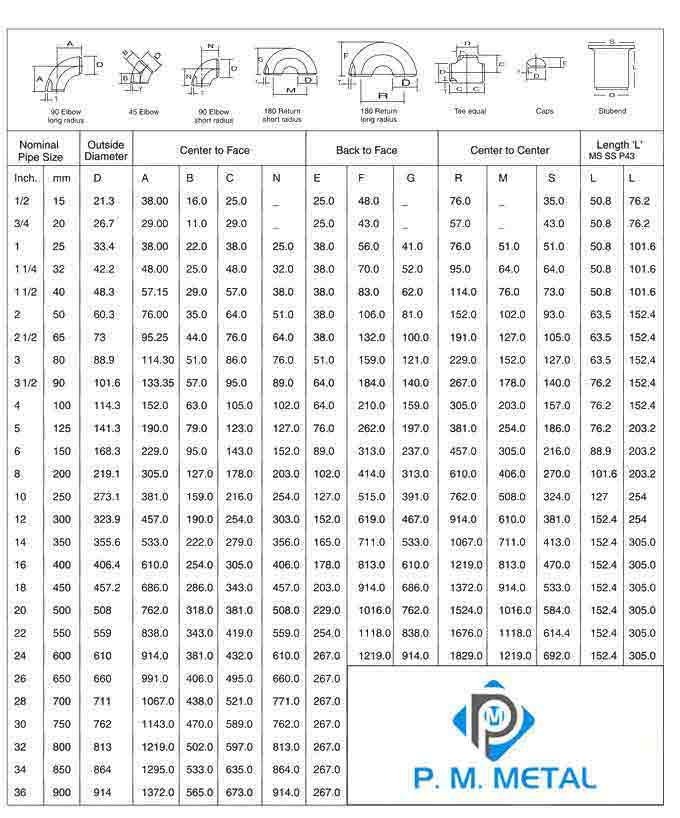

Stainless Steel 304L Welded Pipe Fittings Size Chart

| Product | Size* | Wall Thickness** | Seamless | Welded |

|---|---|---|---|---|

| Reducer | 1/2"-24" | Schedule 10S~XXS | √ | √ |

| 8"-104" | Schedule 5S~80S/XS | √ | ||

| Tee | 1/2"-24" | Schedule 10S~XXS | √ | √ |

| 8"-104" | Schedule 5S~80S/XS | √ | ||

| Lap Joint Stub End | 1/2"-24" | Schedule 5S~80S/XS | √ | √ |

| 8"-80" | Schedule 5S~80S/XS | √ | ||

| Elbow | 1/2"-24" | Schedule 10S~XXS | √ | √ |

| 8"-104" | Schedule 5S~80S/XS | √ | ||

| Cap | 1/2"-80" | Schedule 10S~SCH160 | √ |

Stainless Steel 304L Pipe Fittings Heat Treatment

- 304L is not hardenable by heat treatment. Cold working increases tensile strength and hardness. Annealing range is between 1850° and 2050°F. Cool rapidly.

Supply ASTM A403 WP304L Pipe Bend/ Return Bends, UNS S30403 Tee and Stainless Steel 304L Pipe Cap, Check Properties, dimensions and standard of SS 304L Fittings, 45/ 90/ 180 Degree EN 10253-2 Din 1.4307 Elbow material in India

SS 304L Buttweld Pipe Fittings Tolerance

| ASME B16.9 Fittings Tolerance | Reducers & Lap Joint Stub End |

90 Degree & 45 Degree Elbows & Tees |

Pipe Caps | |||

|---|---|---|---|---|---|---|

| ASME B16.9 Buttweld Fitting (Normal Pipe Size) | I. D. at End |

O. D. at Bevel |

Wall Thick. T | Over-all Length H |

Center-to-End Dimension A ,C ,B |

Over-all Length F |

| 1/2 to 2-1/2 | +0.06 | Not less than 87.5% of nominal thickness |

+/- 0.06 | +/- 0.06 | +/- 0.12 | |

| -0.03 | ||||||

| 3 to 3-1/2 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.12 | |

| 4 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.12 | |

| 5 to 8 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.25 | |

| 10 to 18 | +/- 0.12 | +0.16 | +/- 0.09 | +/- 0.09 | +/- 0.25 | |

| -0.12 | ||||||

| 20 to 24 | +/- 0.19 | +0.25 | +/- 0.09 | +/- 0.09 | +/- 0.25 | |

| -0.19 | ||||||

| 26 to 30 | +/- 0.19 | +0.25 | +/- 0.19 | +/- 0.12 | +/- 0.38 | |

| -0.19 | ||||||

| 32 to 48 | +/- 0.19 | +0.25 | +/- 0.19 | +/- 0.19 | +/- 0.38 | |

| -0.19 | ||||||

ASTM A403 SS WP304L Pipe Fitting Testing

- Hardness test

- Flaring test

- Flattening test

- Positive material identification test

- Mechanical test

- Intergranular corrosion test

- Macro test

- Chemical test

- Pitting resistance test

Types of Stainless Steel 304L Pipe Fittings

SS DIN 1.4306 Pipe Fittings Weight Chart

| NPS (Normal Size Of Steel Pipe) | Schedule 40S | Schedule 10S | Schedule 80S | ||||||

|---|---|---|---|---|---|---|---|---|---|

| ASME B16.9 Butt weld 45 Deg Elbows | ASME B16.9 Butt weld 90 Deg Elbows | ASME B16.9 Butt weld Equal Tee | ASME B16.9 Butt weld 45 Deg Elbow | ASME B16.9 Butt weld 90 Deg Elbow | ASME B16.9 Butt weld Equal Tee | ASME B16.9 Butt weld 45 Deg Elbow | ASME B16.9 Butt weld 90 Deg Elbow | ASME B16.9 Butt weld Equal Tee | |

| 8 | 0.02 | 0.03 | 0.06 | 0.01 | 0.02 | 0.03 | 0.03 | 0.04 | 0.07 |

| 10 | 0.02 | 0.03 | 0.03 | 0.02 | 0.03 | 0.05 | 0.04 | 0.06 | 0.09 |

| 15 | 0.04 | 0.08 | 0.10 | 0.03 | 0.06 | 0.09 | 0.05 | 0.10 | 0.14 |

| 20 | 0.04 | 0.08 | 0.17 | 0.03 | 0.07 | 0.13 | 0.05 | 0.11 | 0.20 |

| 25 | 0.11 | 0.15 | 0.29 | 0.08 | 0.14 | 0.28 | 0.14 | 0.22 | 0.38 |

| 32 | 0.17 | 0.26 | 0.59 | 0.11 | 0.23 | 0.49 | 0.23 | 0.40 | 0.68 |

| 40 | 0.23 | 0.40 | 0.86 | 0.17 | 0.30 | 0.68 | 0.29 | 0.51 | 1.02 |

| 50 | 0.4 | 0.70 | 1.28 | 0.25 | 0.50 | 0.85 | 0.59 | 0.91 | 1.59 |

| 65 | 0.77 | 1.40 | 2.19 | 0.48 | 0.85 | 1.41 | 0.99 | 1.81 | 3.13 |

| 80 | 1.08 | 2.20 | 3.31 | 0.63 | 1.25 | 1.77 | 1.50 | 2.97 | 4.45 |

| 90 | 1.42 | 2.83 | 4.08 | 0.75 | 1.70 | 2.67 | 2.00 | 4.00 | 5.44 |

| 100 | 2.09 | 4.47 | 5.27 | 1.08 | 2.10 | 3.46 | 2.81 | 6.18 | 7.71 |

| 150 | 5.44 | 10.89 | 10.99 | 2.72 | 5.45 | 8.07 | 8.16 | 16.32 | 13.61 |

| 200 | 10.77 | 21.54 | 20.91 | 5.33 | 10.20 | 15.65 | 16.56 | 33.11 | 28.12 |

| 250 | 19.27 | 38.56 | 35.38 | 9.75 | 18.15 | 26.46 | 25.86 | 51.71 | 49.90 |

| 300 | 29.71 | 59.42 | 62.14 | 13.62 | 25.80 | 39.46 | 39.69 | 79.38 | 83.91 |

Stainless Steel 304L Fittings Pressure Rating

| ASME B16.9 Pressure Ratings | |||||

|---|---|---|---|---|---|

| ASME B16.9 Fittings Temperature Ratings | Types Of Pressure Ratings Class | ||||

| Class 150# | Class 300# | ||||

| 1 1/4 - 2 (Inch) | 1/4 - 1 (Inch) | 2 1/2 - 3 (Inch) | |||

| (oC) | (oF) | ||||

| -29 to 66 | -20 to 150 | 300 | 1500 | 2000 | 1000 |

| 93 | 200 | 265 | 1350 | 1785 | 910 |

| 121 | 250 | 225 | 1200 | 1575 | 825 |

| 149 | 300 | 185 | 1050 | 1360 | 735 |

| 177 | 350 | 150 | 900 | 1150 | 650 |

| 204 | 400 | - | 750 | 935 | 560 |

| 232 | 450 | - | 600 | 725 | 475 |

| 260 | 500 | - | 450 | 510 | 385 |

| 288 | 550 | - | 300 | 300 | 300 |

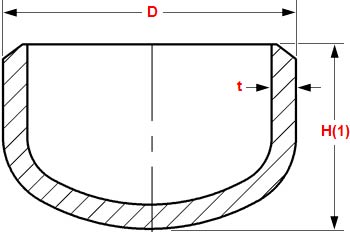

ASTM A403 WP304L End Cap Dimensions

| NPS | LENGTH H | O.D. D | LENGTH H1 |

|---|---|---|---|

| 1/2 | 25 | 21.3 | 25 |

| 3/4 | 25 | 26.7 | 25 |

| 1 | 38 | 33.4 | 38 |

| 1.1/4 | 38 | 42.2 | 38 |

| 1.1/2 | 38 | 48.3 | 38 |

| 2 | 38 | 60.3 | 44 |

| 2.1/2 | 38 | 73 | 51 |

| 3 | 51 | 88.9 | 64 |

| 3.1/2 | 64 | 101.6 | 76 |

| 4 | 64 | 114.3 | 76 |

| 5 | 76 | 141.3 | 89 |

| 6 | 89 | 168.3 | 102 |

| 8 | 102 | 219.1 | 127 |

| 10 | 127 | 273 | 152 |

| 12 | 152 | 323.8 | 178 |

| 14 | 165 | 355.6 | 191 |

| 16 | 178 | 406.4 | 203 |

| NPS | LENGTH H | O.D. D | LENGTH H1 |

|---|---|---|---|

| 18 | 203 | 457 | 229 |

| 20 | 229 | 508 | 254 |

| 22 | 254 | 559 | 254 |

| 24 | 267 | 610 | 305 |

| 26 | 267 | 660 | |

| 28 | 267 | 711 | |

| 30 | 267 | 762 | |

| 32 | 267 | 813 | |

| 34 | 237 | 864 | |

| 36 | 267 | 914 | |

| 38 | 305 | 965 | |

| 40 | 305 | 1016 | |

| 42 | 305 | 1067 | |

| 44 | 343 | 1118 | |

| 46 | 343 | 1168 | |

| 48 | 343 | 1219 |

Butt welded seamless SCH40 ASTM A403 Gr WP304L Stub End manufacturer in India and View MSS SP43 DIN 2605 type 3 1.4307 Stainless Steel Elbow and UNS S30403 Equal Tee upto 72 Inch in Mumbai, 100% radiographed

Dimensional Tolerances Straight Tees ASME B16.9

| Nominal Pipe Sizes | 10 to 18 | 3 to 3.1/2 | 5 to 8 | 1/2 to 2.1/2 | 32 to 48 | 4 | 20 to 24 | 26 to 30 |

|---|---|---|---|---|---|---|---|---|

| Inside Dia at End | 3.2 | 1.6 | 1.6 | 0.8 | +6.4 -4.8 | 1.6 | 4.8 | +6.4 -4.8 |

| Out Dia at Bevel (D) | +4 -3.2 | 1.6 | +2.4 -1.6 | +1.6 -0.8 | +6.4 -4.8 | 1.6 | +6.4 -4.8 | +6.4 -4.8 |

| Center to End (C / M) | 2 | 2 | 2 | 2 | 5 | 2 | 2 | 3 |

| Wall Thk (t) | Not less than 87.5% of Nominal Wall Thickness | |||||||

304L Stainless Steel Pipe Fittings Thermal Expansion

| Property | Value |

|---|---|

| Thermal Conductivity | 16.2W/m.K |

| Thermal Expansion | 17.2 x 10-6 /K |

| Electrical Resistivity | 0.072 x 10-6 Ω .m |

304L Stainless Steel Fittings Corrosion Resistance

- 304L has excellent corrosion resistance in many environments and when in contact with different corrosive media. Pitting and crevice corrosion can occur in environments containing chlorides. Stress corrosion cracking can occur above 60°C.

ASTM A403 Gr WP304L Elbows Dimensions

| NPS | 45° 3D Center to End B | 45° Long Radius Center to End B | 90° Long Radius Center to End A | 90° 3D Center to End A | Outer Dia D |

|---|---|---|---|---|---|

| 3.1/2 | 111 | 57 | 133 | 267 | 101.6 |

| 4 | 127 | 64 | 152 | 305 | 114.3 |

| 5 | 157 | 79 | 190 | 381 | 141.3 |

| 6 | 189 | 95 | 229 | 457 | 168.3 |

| 8 | 252 | 127 | 305 | 610 | 219.1 |

| 1/2 | 16 | 38 | 21.3 | ||

| 3/4 | 24 | 19 | 38 | 57 | 26.7 |

| 1 | 31 | 22 | 38 | 76 | 33.4 |

| 1.1/4 | 39 | 25 | 48 | 95 | 42.2 |

| 1.1/2 | 47 | 29 | 57 | 114 | 48.3 |

| 2 | 63 | 35 | 76 | 152 | 60.3 |

| 2.1/2 | 79 | 44 | 95 | 190 | 73 |

| 3 | 95 | 51 | 114 | 229 | 88.9 |

| 10 | 316 | 159 | 381 | 762 | 273 |

| 12 | 378 | 190 | 457 | 914 | 323.8 |

| 14 | 441 | 222 | 533 | 1067 | 355.6 |

| 16 | 505 | 254 | 610 | 1219 | 406.4 |

| NPS | 45° Long Radius Center to End B | 45° 3D Center to End B | 90° Long Radius Center to End A | 90° 3D Center to End A | Outer Dia. D |

|---|---|---|---|---|---|

| 34 | 533 | 1073 | 1295 | 2591 | 864 |

| 36 | 565 | 1135 | 1372 | 2743 | 914 |

| 18 | 286 | 568 | 686 | 1372 | 457 |

| 20 | 318 | 632 | 762 | 1524 | 508 |

| 22 | 343 | 694 | 838 | 1676 | 559 |

| 24 | 381 | 757 | 914 | 1829 | 610 |

| 26 | 406 | 821 | 991 | 1981 | 660 |

| 28 | 438 | 883 | 1067 | 2134 | 711 |

| 30 | 470 | 946 | 1143 | 2286 | 762 |

| 32 | 502 | 1010 | 1219 | 2438 | 813 |

| 38 | 600 | 1200 | 1448 | 2896 | 965 |

| 40 | 632 | 1264 | 1524 | 3048 | 1016 |

| 42 | 660 | 1326 | 1600 | 3200 | 1067 |

| 44 | 695 | 1389 | 1676 | 3353 | 1118 |

| 46 | 727 | 1453 | 1753 | 3505 | 1168 |

| 48 | 759 | 1516 | 1829 | 3658 | 1219 |

ASTM A403 WP304L Butt Weld Elbows Dimensional Tolerances

| Nominal Pipe Sizes | 5 to 8 | 3 to 3.1/2 | 4 | 1/2 to 2.1/2 |

|---|---|---|---|---|

| Inside Dia at End | 1.6 | 1.6 | 1.6 | 0.8 |

| Outside Dia at Bevel (D) | + 2.4 - 1.6 | 1.6 | 1.6 | + 1.6 - 0.8 |

| Center to End LR (A/B) | 2 | 2 | 2 | 2 |

| Nominal Pipe Size | 32 to 48 | 20 to 24 | 26 to 30 | 10 to 18 |

| Center to End 3D (A/B) | 3 | 3 | 3 | 3 |

| Outside Dia at Bevel (D) | + 6.4 - 4.8 | + 6.4 - 4.8 | + 6.4 - 4.8 | + 4 - 3.2 |

| Center to End LR (A/B) | 5 | 2 | 3 | 2 |

| Inside Dia at End | + 6.4 - 4.8 | 4.8 | + 6.4 - 4.8 | 3.2 |

| Center to End 3D (A/B) | 6 | 3 | 6 | 3 |

| Wall Thickness (t) | Not less than 87.5% of Nominal Wall Thickness | |||

Sus 304L Stainless Steel Long Radius Elbow Dimension Chart

SA 403 WP 304L TEE Dimension

| NPS | Center to End M | Outside Dia D | Center to End C |

|---|---|---|---|

| 1/2 | 25 | 21.3 | 25 |

| 3/4 | 29 | 26.7 | 29 |

| 1 | 38 | 33.4 | 38 |

| 1.1/4 | 48 | 42.2 | 48 |

| 1.1/2 | 57 | 48.3 | 57 |

| 2 | 64 | 60.3 | 64 |

| 2.1/2 | 76 | 73 | 76 |

| 3 | 86 | 88.9 | 86 |

| 3.1/2 | 95 | 101.6 | 95 |

| 4 | 114.3 | 105 | 105 |

| 5 | 141.3 | 124 | 124 |

| 6 | 168.3 | 143 | 143 |

| 8 | 219.1 | 178 | 178 |

| 10 | 273 | 216 | 216 |

| 12 | 323.8 | 254 | 254 |

| 14 | 355.6 | 279 | 279 |

| 16 | 406.4 | 305 | 305 |

| 18 | 457 | 343 | 343 |

| 20 | 508 | 381 | 381 |

| 22 | 559 | 419 | 419 |

| 24 | 610 | 432 | 432 |

| 26 | 495 | 660 | 495 |

| 28 | 521 | 711 | 521 |

| 30 | 559 | 762 | 559 |

| 32 | 597 | 813 | 597 |

| 34 | 635 | 864 | 635 |

| 36 | 673 | 914 | 673 |

| 38 | 711 | 965 | 711 |

| 40 | 749 | 1016 | 749 |

| 42 | 762 | 1067 | 711 |

| 44 | 813 | 1118 | 762 |

| 46 | 851 | 1168 | 800 |

| 48 | 889 | 1219 | 838 |

Stainless Steel 304L Pipe Fittings International Standards

| Standard | Material | Description |

|---|---|---|

| MSS SP43 | 304L SS buttweld fittings | Wrought stainless steel butt-welding pipe fittings. Wrought and Fabricated Butt-Welding pipe Fittings for Low Pressure, Corrosion Resistant Applications |

| ASTM A403/ A403M | Stainless Steel 304L fittings | Wrought austenitic stainless steel fittings. |

| ISO 4144 | Stainless Steel UNS S30403 threaded fittings | SS fittings threaded to ISO 7-1. |

| ASTM A815/ A815M | ASTM A403 WP304L pipe fitting | Wrought ferritic, ferritic/austenitic and martensitic stainless steel fittings. |

| MSS SP-95 | SA 403 Gr WP304L Swage Nipple | Bull Plugs and Swage(d) Nipples |

| ANSI / ASME B16.9 | SS 304L butt welding fittings | Factory-made wrought steel butt weld fittings. |

| BS3799 | A403 WP304L socket weld fittings | Specification for SS pipe fittings, screwed and Socket-welding for the petroleum industry |

| ANSI / ASME B16.11 | 304L Stainless Steel Forged Fittings | Forged steel fittings socket and threaded. Socket and Threaded Forged Fittings |

| ASME B16.28 | SA 403 WP304L Short Radius Elbow | ‘Wrought Steel Buttweld Short Radius Elbows and Returns’ |

| ANSI / ASME B16.5 | SS UNS S30403 flanged fittings | Steel pipe flanges and other flanged fittings. |

| ANSI / ASME B16.25 | ASTM A403 Gr WP304L Butt-welding ends | Butt-weld ends. |

| ASME B16.25 | ASTM A403 Grade WP304L buttweld ends | ‘Buttwelding Pipe Ends’ |

Dimensional Tolerances of End Caps

| Nominal Pipe Size | 3 to 3.1/2 | 1/2 to 2.1/2 | 5 to 8 | 4 |

|---|---|---|---|---|

| Outside Diameter at Bevel (D) | 1.6 | + 1.6 - 0.8 | + 2.4 - 1.6 | 1.6 |

| Inside Diameter at End | 1.6 | 0.8 | 1.6 | 1.6 |

| Overall Length (H) | 3 | 3 | 6 | 3 |

| Nominal Pipe Size | 20 to 24 | 10 to 18 | 32 to 48 | 26 to 30 |

| Outside Diameter at Bevel (D) | + 6.4 - 4.8 | + 4 - 3.2 | + 6.4 - 4.8 | + 6.4 - 4.8 |

| Inside Diameter at End | 4.8 | 3.2 | + 6.4 - 4.8 | + 6.4 - 4.8 |

| Overall Length (H) | 6 | 6 | 10 | 10 |

| Wall Thickness (t) | Not less than 87.5% of Nominal Wall Thickness | |||

A403 WP304L Pipe Bend Dimensions

90° BENDS

| Size (in.) |

T (in.) |

Pressure Rating (psi) |

Long Radius1 | Short Radius | ||||

|---|---|---|---|---|---|---|---|---|

| B (in.) |

R (in.) |

Weight (lbs.) |

A (in.) |

R (in.) |

Weight (lbs.) |

|||

| 4 | 0.52 | 250 | 9 | 7 | 50 | 6.5 | 4.5 | 40 |

| 6 | 0.55 | 250 | 11.5 | 9.5 | 80 | 8 | 6 | 65 |

| 8 | 0.6 | 250 | 14 | 12 | 140 | 9 | 7 | 105 |

| 10 | 0.68 | 250 | 16.5 | 14.5 | 215 | 11 | 9 | 165 |

| 12 | 0.75 | 250 | 19 | 17 | 325 | 12 | 10 | 240 |

| 14 | 0.66 | 250 | 21.5 | 19 | 385 | 14 | 11.5 | 290 |

| 16 | 0.7 | 250 | 24 | 21.5 | 505 | 15 | 12.5 | 370 |

| 18 | 0.75 | 250 | 26.5 | 24 | 630 | 16.5 | 14 | 450 |

| 20 | 0.8 | 250 | 29 | 26.5 | 810 | 18 | 15.5 | 575 |

| 24 | 0.89 | 250 | 34 | 30.5 | 1240 | 22 | 18.5 | 900 |

| 30 | 1.03 | 250 | 41.5 | 38 | 2105 | 25 | 21.5 | 1430 |

| 36 | 1.15 | 250 | 49 | 45.5 | 3285 | 28 | 24.5 | 2135 |

| 42 | 1.28 | 250 | 56.5 | 53 | 4865 | 31 | 27.5 | 3055 |

| 48 | 1.42 | 250 | 64 | 60.5 | 6790 | 34 | 30.5 | 4090 |

| 54 | 0.9 | 2502 | - | - | - | 39 | 34.3 | 3740 |

| 60 | 0.94 | 2502 | - | - | - | 43 | 36.5 | 4965 |

| 64 | 0.99 | 2502 | - | - | - | 48 | 38.8 | 6745 |

45° BENDS

| Size (in.) |

T (in.) |

Pressure Rating (psi) |

R (in.) |

C (in.) |

Weight (lbs.) |

|---|---|---|---|---|---|

| 4 | 0.52 | 250 | 4.81 | 4 | 35 |

| 6 | 0.55 | 250 | 7.25 | 5 | 55 |

| 8 | 0.6 | 250 | 8.44 | 5.5 | 85 |

| 10 | 0.68 | 250 | 10.88 | 6.5 | 130 |

| 12 | 0.75 | 250 | 13.25 | 7.5 | 200 |

| 14 | 0.66 | 250 | 12.06 | 7.5 | 220 |

| 16 | 0.7 | 250 | 13.25 | 8 | 280 |

| 18 | 0.75 | 250 | 14.5 | 8.5 | 330 |

| 20 | 0.8 | 250 | 16.88 | 9.5 | 425 |

| 24 | 0.89 | 250 | 18.12 | 11 | 630 |

| 30 | 1.03 | 250 | 27.75 | 15 | 1120 |

| 36 | 1.15 | 250 | 35 | 18 | 1755 |

| 42 | 1.28 | 250 | 42.25 | 21 | 2600 |

| 48 | 1.42 | 250 | 49.5 | 24 | 3575 |

| 54 | 0.9 | 2505 | 42.32 | 20.5 | 2735 |

| 60 | 0.94 | 2505 | 44.08 | 23.5 | 3790 |

| 64 | 0.99 | 2505 | 45.85 | 25 | 5105 |

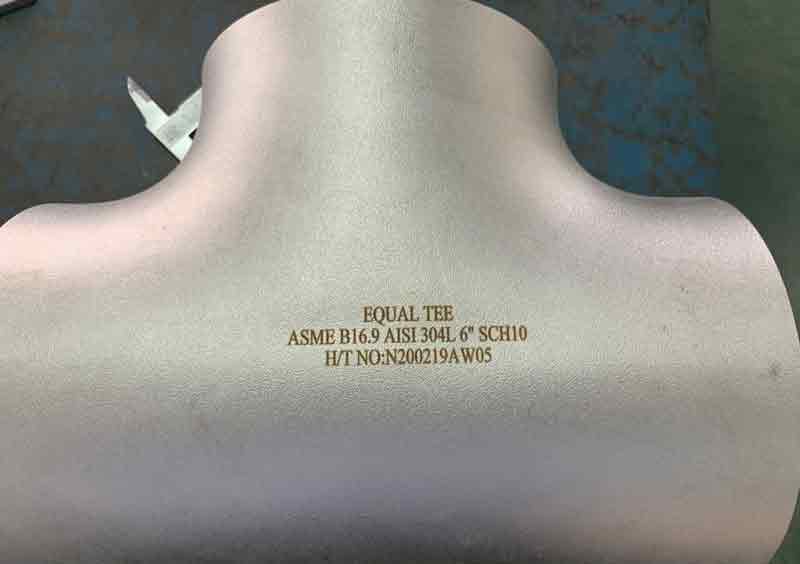

SS 304L Butt Weld Fittings Marking

- Rating Designation

- Material Designation

- "WP" in grade symbol

- Grade

- Schedule number or nominal wall thickness

- Heat Code

- Manufacturer’s Name or Symbol

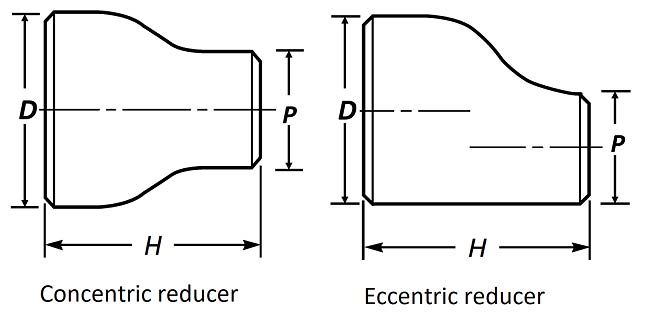

UNS S30403 Reducer Dimension Chart

| NPS | Outside Dia D |

Outside Dia D1 |

Length H |

|---|---|---|---|

| 2.1/2 ▸ 2 | 73 | 60.3 | 89 |

| 3 ▸ 1.1/4 | 88.9 | 42.2 | 89 |

| 3 ▸ 1.1/2 | 88.9 | 48.3 | 89 |

| 3 ▸ 2 | 88.9 | 60.3 | 89 |

| 3 ▸ 2.1/2 | 88.9 | 73 | 89 |

| 3.1/2 ▸ 1.1/4 | 101.6 | 42.2 | 102 |

| 3.1/2 ▸ 1.1/2 | 101.6 | 48.3 | 102 |

| 3.1/2 ▸ 2 | 101.6 | 60.3 | 102 |

| 3.1/2 ▸ 2.1/2 | 101.6 | 73 | 102 |

| 3.1/2 ▸ 3 | 101.6 | 88.9 | 102 |

| 4 ▸ 1.1/2 | 114.3 | 48.3 | 102 |

| 4 ▸ 2 | 114.3 | 60.3 | 102 |

| 4 ▸ 2.1/2 | 114.3 | 73 | 102 |

| 4 ▸ 3 | 114.3 | 88.9 | 102 |

| 4 ▸ 3.1/2 | 114.3 | 101.6 | 102 |

| 5 ▸ 2 | 141.3 | 60.3 | 127 |

| 5 ▸ 2.1/2 | 141.3 | 73 | 127 |

| 3/4 ▸ 1/2 | 26.7 | 21.3 | 38 |

| 1 ▸ 1/2 | 33.4 | 21.3 | 51 |

| 1 ▸ 3/4 | 33.4 | 26.7 | 51 |

| 1.1/4 ▸ 1/2 | 42.2 | 21.3 | 51 |

| 1.1/4 ▸ 3/4 | 42.2 | 26.7 | 51 |

| 1.1/4 ▸ 1 | 42.2 | 33.4 | 51 |

| 1.1/2 ▸ 1/2 | 48.3 | 21.3 | 64 |

| 1.1/2 ▸ 3/4 | 48.3 | 26.7 | 64 |

| 1.1/2 ▸ 1 | 48.3 | 33.4 | 64 |

| 1.1/2 ▸ 1.1/4 | 48.3 | 42.2 | 64 |

| 2 ▸ 3/4 | 60.3 | 26.7 | 76 |

| 2 ▸ 1 | 60.3 | 33.4 | 76 |

| 2 ▸ 1.1/4 | 60.3 | 42.2 | 76 |

| 2 ▸ 1.1/2 | 60.3 | 48.3 | 76 |

| 2.1/2 ▸ 1 | 73 | 33.4 | 89 |

| 2.1/2 ▸ 1.1/4 | 73 | 42.2 | 89 |

| 2.1/2 ▸ 1.1/2 | 73 | 48.3 | 89 |

| 5 ▸ 3 | 141.3 | 88.9 | 127 |

| 5 ▸ 3.1/2 | 141.3 | 101.6 | 127 |

| 5 ▸ 4 | 141.3 | 114.3 | 127 |

| 6 ▸ 2.1/2 | 168.3 | 73 | 140 |

| 6 ▸ 3 | 168.3 | 88.9 | 140 |

| 6 ▸ 3.1/2 | 168.3 | 101.6 | 140 |

| 6 ▸ 4 | 168.3 | 114.3 | 140 |

| 6 ▸ 5 | 168.3 | 141.3 | 140 |

| 8 ▸ 3.1/2 | 219.1 | 101.6 | 152 |

| 8 ▸ 4 | 219.1 | 114.3 | 152 |

| 8 ▸ 5 | 219.1 | 141.3 | 152 |

| 8 ▸ 6 | 219.1 | 168.3 | 152 |

| 10 ▸ 4 | 273 | 114.3 | 178 |

| 10 ▸ 5 | 273 | 141.3 | 178 |

| 10 ▸ 6 | 273 | 168.3 | 178 |

| 10 ▸ 8 | 273 | 219.1 | 178 |

| 12 ▸ 5 | 323.9 | 141.3 | 203 |

| 12 ▸ 6 | 323.9 | 168.3 | 203 |

| 12 ▸ 8 | 323.9 | 219.1 | 203 |

| 12 ▸ 10 | 323.9 | 273 | 203 |

| 14 ▸ 6 | 355.6 | 168.3 | 330 |

| 14 ▸ 8 | 355.6 | 219.1 | 330 |

| 14 ▸ 10 | 355.6 | 273 | 330 |

| 14 ▸ 12 | 355.6 | 323.9 | 330 |

| 16 ▸ 8 | 406.4 | 219 | 356 |

| 16 ▸ 10 | 406.4 | 273 | 356 |

| 16 ▸ 12 | 406.4 | 323.9 | 356 |

| 16 ▸ 14 | 406.4 | 355.6 | 356 |

| 18 ▸ 10 | 457 | 273 | 381 |

| 18 ▸ 12 | 457 | 323.9 | 381 |

| 18 ▸ 14 | 457 | 355.6 | 381 |

| 18 ▸ 16 | 457 | 406.4 | 381 |

| 20 ▸ 12 | 508 | 323.9 | 508 |

| 20 ▸ 14 | 508 | 355.6 | 508 |

| 20 ▸ 16 | 508 | 406.4 | 508 |

| 20 ▸ 18 | 508 | 457 | 508 |

| 22 ▸ 14 | 559 | 355.6 | 508 |

| 22 ▸ 16 | 559 | 406.4 | 508 |

| 22 ▸ 18 | 559 | 457 | 508 |

| 22 ▸ 20 | 559 | 508 | 508 |

| 24 ▸ 16 | 610 | 406.4 | 508 |

| 24 ▸ 18 | 610 | 457 | 508 |

| 24 ▸ 20 | 610 | 508 | 508 |

| 24 ▸ 22 | 610 | 559 | 508 |

| 26 ▸ 18 | 660 | 457 | 610 |

| 26 ▸ 20 | 660 | 508 | 610 |

| 26 ▸ 22 | 660 | 559 | 610 |

| 26 ▸ 24 | 660 | 610 | 610 |

| 28 ▸ 18 | 711 | 457 | 610 |

| 28 ▸ 20 | 711 | 508 | 610 |

| 28 ▸ 24 | 711 | 610 | 610 |

| 28 ▸ 26 | 711 | 660 | 610 |

| 30 ▸ 20 | 762 | 508 | 610 |

| 30 ▸ 24 | 762 | 610 | 610 |

| 30 ▸ 26 | 762 | 660 | 610 |

| 30 ▸ 28 | 762 | 711 | 610 |

| 32 ▸ 24 | 813 | 610 | 610 |

| 32 ▸ 26 | 813 | 660 | 610 |

| 32 ▸ 28 | 813 | 711 | 610 |

| 32 ▸ 30 | 813 | 762 | 610 |

| 34 ▸ 24 | 864 | 610 | 610 |

| 34 ▸ 26 | 864 | 660 | 610 |

| 34 ▸ 30 | 864 | 762 | 610 |

| 34 ▸ 32 | 864 | 813 | 610 |

| 36 ▸ 24 | 914 | 610 | 610 |

| 36 ▸ 26 | 914 | 660 | 610 |

| 36 ▸ 30 | 914 | 762 | 610 |

| 36 ▸ 32 | 914 | 813 | 610 |

| 36 ▸ 34 | 914 | 864 | 610 |

| 38 ▸ 26 | 965 | 660 | 610 |

| 38 ▸ 28 | 965 | 711 | 610 |

| 38 ▸ 30 | 965 | 762 | 610 |

| 38 ▸ 32 | 965 | 813 | 610 |

| 38 ▸ 34 | 965 | 864 | 610 |

| 38 ▸ 36 | 965 | 914 | 610 |

| 40 ▸ 30 | 1016 | 762 | 610 |

| 40 ▸ 32 | 1016 | 813 | 610 |

| 40 ▸ 34 | 1016 | 864 | 610 |

| 40 ▸ 36 | 1016 | 914 | 610 |

| 40 ▸ 38 | 1016 | 965 | 610 |

| Dimensional Tolerances of Eccentric and Concentric Reducers ASME B16.9 | ||||

|---|---|---|---|---|

| Nominal Pipe Sizes | 5 to 8 | 3 to 3.1/2 | 4 | 1/2 to 2.1/2 |

| I.D at End | 1.6 | 1.6 | 1.6 | 0.8 |

| O.D at Bevel (D) |

+ 2.4 - 1.6 |

1.6 | 1.6 | + 1.6 - 0.8 |

| Overall Length (H) | 2 | 2 | 2 | 2 |

| Nominal Pipe Sizes | 32 to 48 | 20 to 24 | 26 to 30 | 10 to 18 |

| I.D at End | + 6.4 - 4.8 |

4.8 | + 6.4 - 4.8 |

3.2 |

| O.D at Bevel (D) |

+ 6.4 - 4.8 |

+ 6.4 - 4.8 |

+ 6.4 - 4.8 |

+ 4 - 3.2 |

| Overall Length (H) | 5 | 2 | 5 | 2 |

| Wall Thickness (t) | Not less than 87.5% of Nominal Wall Thk. | |||

| Dimensional tolerances are in mm unless otherwise indicated and are equal ± except as noted. | ||||

SS 304L Seamless Fittings Value added Services

- Polish (Electro & Commercial)

- Heat Treatment

- Annealed

- Pickling, Polish

- Rolling

- Bending

- Forging

- Minor Fabrication Etc.

View 304L Stainless Steel Pipe Fittings Supplier in India. Contact us to buy ISO 3419 Seamless A403 WP304L Reducing/ Equal/ Unequal/ Lateral Tee upto 24 Inch custom sizes at factory price, large stock of welded A403 WP304L Buttweld Fittings, SA 403 WP 304L Tee and DIN 1.4307 Long and Short Radius Elbow in Mumbai

Stainless Steel 304L Pipe Fittings Price list

| Products | Fitting Pipe Size | 304L Stainless Steel |

|---|---|---|

| PIPE FITTING STAINLESS STEEL SA 403 WP 304L DN 50X40,SCH 40SX40S,ECCENTRIC REDUCER,,B ER30020D40S40S(3PCS) | 1/8 in x 1/8 in | $5.60 |

| STAINLESS STEEL PIPE FITTING SS 304L TC CLAMP SIZE 1 & 1.5(2500 PCS) | 3/8 in x 3/8 in | $8.00 |

| PIPE FITTING STAINLESS STEEL SA 403 GR WP304L DN150,SCH 40S,45 DEGREE ELBOW(LR),ASME,BW,SMLS,DIM,AS PER ASM | 1/2 in x 1/2 in | $16.13 |

| PIPE FITTING STAINLESS STEEL A403 GR WP304L STUB END SCH10S 304L MSS TP B A403 W (4PCS) | 1 in x 1 in | $35.35 |

| STAINLESS STEEL PIPE FITTING VALVE,CLAMP,UNION GRADE 304L | 1 1/4 in x 1 1/4 in | $34.45 |

| PIPE FITTING STAINLESS STEEL SA 403 GR WP304L DN25,SCH 10S,EQUAL TEE,ASME,BW,SMLS,DIM,AS PER ASME/ANSI B16.9 | 1 1/2 in x 1 1/2 in | $51.04 |

| PIPE FITTING STAINLESS STEEL GR WP304L DN15,SCH 80S,45 DEGREE ELBOW(LR),BW,SMLS B16.9 | 2 in x 2 in | $58.37 |

| PIPE FITTING STAINLESS STEEL GR WP304L DN50,SCH 80,EQUAL TEE ,BW,SMLS B16.9 | 3 in x 3 in | $279.54 |

ASTM A403 Wp304L Buttweld Pipe Fittings Density

| Property | Value |

|---|---|

| Density | 8.00 Kg/m3 |

SS 304L Pipe Fittings Inventory

| ASTM A403 WP304L Elbow | 304L SS Buttweld 90 deg. Elbow |

| Stainless Steel 304L 90 Deg Elbow | Stainless Steel UNS S30403 Pipe Elbow |

| 304L Stainless Steel 2D Elbow | ASTM A403 SS WP304L Pipe Fitting |

| ASME SA 403 WP 304L Concentric Reducer | 304L Stainless Steel Buttweld Fittings |

| WP304L Eccentric Reducer | SS 304L Butt weld Fittings |

| SCH 40 SS 304L 3D Elbow | SS DIN 1.4306 Pipe Fittings |

| UNS S30403 Equal Tee | Stainless Steel 304L Long / Short Radius Elbow |

| WNR 1.4307 Reducing Tee | Stainless Steel 304L Fittings |

| A403 WP304L End Cap | 304L Stainless Steel Pipe Fittings |

| SS 304L Fittings Material | Ss 304L Buttweld Fittings |

| SS 304L Weld Fittings | Astm A403 Gr Wp 304L Elbow |

| ASME SA403 WP304L Reducer | Sa 403 Wp 304L Tee |

| ASME SA403 WP304L Pipe End Cap | Ss 304L Buttweld Pipe Fittings |

| SS 304L Seamless Fittings | 304L Stainless Steel Fittings |

| 304L Stainless Steel Elbow | Ss 304L Fittings |

| ASTM A403 WP304L Tee | A403 Wp304L Tee |

| ASTM A403 WP304L Pipe Fittings | Sa403 Wp304L Pipe End Cap |

| SS 304L Equal Tee | Sus 304L Stainless Steel Long Radius Elbow |

| ANSI B16.9 SS WP304L End Pipe Cap | Astm A403 Wp304L Buttweld Pipe Fittings |

| ASME B16.9 SS 304L Seamless Pipe Fittings | Wp304L Elbow Heat Treatment |

| WP304L SS Stub Ends | Stainless Steel 304L Pipe Fittings |

| Stainless Steel 304L Welded Pipe Fittings | Ss 304L Pipe Fittings |

| SS 304L Reducer | Stainless Steel 304L Pipe Fittings |

SS 304L Buttweld Fittings Documentation

- Fumigation Certificates

- Guarantee Letter

- Raw Material Test Reports

- Fumigation Certificates

- Heat Treatment Charts

- Commercial Invoice which includes HS Code

- QAP (Quality Assurance Plan)

- NABL approved Laboratory Test Reports

Searching for

Stainless Steel 304L Pipe Fittings Supplier in your country? Checklist of material we export in the following areas.

ASTM A403 WP304L Fittings

Bangladesh, Jakarta -Indonesia, Dubai, Los Alamos -Mexico, Hong Kong, Turkey, Argentina, Germany, China, Oman, Saudi Arabia (KSA).

A403 WP304L Elbow

Malaysia, Poland, Romania, Indonesia, Malaysia, Iran, Qatar, New Zealand, Brazil, Netherlands, United Arab Emirates (UAE).

304L Stainless Steel Fittings

USA, Chile, Ellington -United States, Canada, Sweden, United States, Greece, Singapore, Vietnam, Mexico, Denmark, Thailand, Finland.

A403 WP304L material

Russia, Belgium, Norway, Egypt, Bahrain, Philippines, South Korea, Peru, Malaysia, Tehran -Iran, Colombia, Italy.

304L Pipe Fittings

Spain, Jakarta, Europe, Australia, Jordan, Dammam -KSA, Japan, Istanbul -Turkey, NY 12203 (USA), Dubai -UAE, Kuala Lumpur.

A403 Grade WP304L Buttweld Fittings

France, Singapore, Taiwan, South Africa, Portugal, Morocco, Czechia, Kuwait, Austria, United Kingdom (UK), Nigeria.