9th Khetwadi Ln, Girgaon, Mumbai, Maharashtra 400004

ASTM B366 UNS N06625 Buttweld Elbow and Alloy 625 Fittings manufacturer in India

Manufacturer of Inconel Pipe Fittings in India, View stock of Nickel Alloy 625 Concentric / Eccentric Reducer, Cap and 2.4856 Tee Fittings according to ASME B16.9 Standard

What is Inconel 625 Pipe Fittings?

Inconel 625 pipe fittings are a standard austenitic grade of high-strength components. The versatile fittings are designed with a superior chemical composition consisting of nickel, chromium, and molybdenum. The outstanding chemical content propels these fittings to showcase excellent corrosion and oxidation resistance properties. The alloy 625 fittings exhibit enhanced tolerance to pitting by acids and crevice corrosion across stress-induced setups. The versatile Nickel 625 pipe fittings perform well in temperatures ranging from sub-zero up to 1800 degrees F. Designed to connect a range of piping types, these fittings play a pivotal role in influencing the flow of fluids and gases within the system.

What is ASME B16.11 Inconel 625 Forged Fittings?

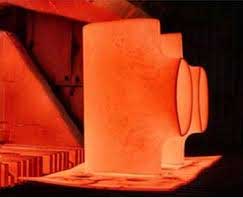

ASME B16.11 Inconel 625 forged fittings are high-strength components designed by forging steel at extreme temperatures. The forged steel is then shaped to desired specifications to form different types of fittings that are resistant and tolerant to different chemical contaminants.

Manufacturer and Supplier of Inconel 625 Stub End and Pipe cap (ASTM B564 UNS N06625) in Mumbai, check sizes, dimension and weight chart of Alloy 625 Long/ Short Radius Elbow

Nickel 625 Reducer Vs ASTM B366 UNS N06625 Tee

Fittings in the Alloy 625 range are designed in different shapes and dimensions. A reducer and tee are frequently used fittings that can be used to meet a range of requirements.

- A Nickel 625 reducer is a device that helps in adopting the shape and size of one pipe to the other and connecting it to the system. Designed in a range of dimensions a reducer can either be eccentric or concentric.

- ASTM B366 UNS N06625 tee is designed in the shape of a T having three openings. They help in transporting the flow across three channels. Tees can either be reduced or equal and are available in a range of designs.

Looking for Inconel Fittings manufacturers? Get Nickel 625 Stub End and DIN 2.4856 Equal / Reducing Tee as per the customer choice, Buy directly from Alloy 625 Buttweld End Cap manufacturers for best deal

Inconel 625 1D Elbow Vs WNR 2.4856 5D Elbow

Elbows are pipe fittings that are used to change the direction of the flow in the piping system. 1D and 5D are common radius bends that are characterized by some major differences.

- A WNR 2.4856 5D elbow is bent 5 times its outer pipe diameter. Inconel 625 1D elbow is a short radius elbow that is bent 1 times its outer diameter.

- A 5D elbow offers better performance and direction change compared to a 1D elbow.

You can compare our price and quality with other Inconel Fittings suppliers in India, we offer Alloy 625 45/90 Degree Elbow with MTC EN 10204 3.1

Types of Inconel 625 Pipe Fittings

Inconel 625 Buttweld Fittings

There are many benefits if you buy from Buttweld 625 Pipe Fittings Manufacturers, like high quality, best price and wide range.

Inconel 625 Elbow

Why don't you directly contact a UNS N06625 Elbow Manufacturer in India? We offer an extensive range of Inconel 625 Pipe Suppliers in Mumbai, free sample before dispatch of complete order.

Inconel 625 Tee

Check below product Inconel 625 Pipe Fittings Manufacturer in India, we use only high quality & tested material to produce Alloy 625 Tee